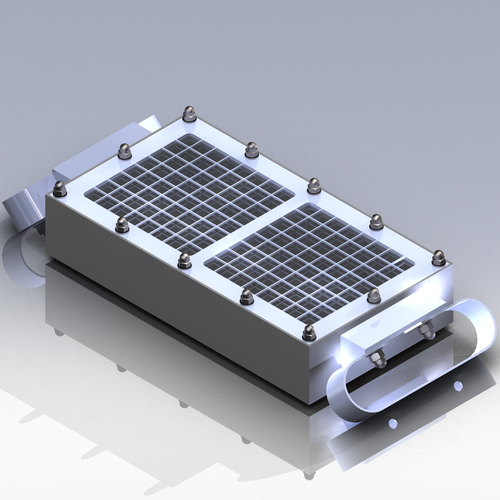

Hydrogen Removal Device

Product Details:

- Noise Level <65 dB

- Drive Type Direct Drive

- Size Standard

- Features High efficiency, corrosion resistance, easy maintenance, long operational life

- Surface Finish Mirror Finish

- Usage & Applications Industrial hydrogen extraction, metallurgy, chemical process, gas purification

- Capacity 500 L/h

- Click to View more

X

Hydrogen Removal Device Price And Quantity

- 10 Unit

Hydrogen Removal Device Product Specifications

- Stainless Steel

- 450mm x 240mm x 700mm

- 2.5 kW

- Silver

- Standard

- High efficiency, corrosion resistance, easy maintenance, long operational life

- Direct Drive

- Advanced Catalyst Filtration

- Polished

- <65 dB

- 0.85 kW

- 40 kg

- Hydrogen Removal Device

- Rectangular

- Electric

- 80 mm

- 220 V

- Industrial hydrogen extraction, metallurgy, chemical process, gas purification

- 500 L/h

- Automatic Lubrication

- Mirror Finish

- 0.5-1.5 MPa

Product Description

Product Description

This device makes natural conviction of hydrogen-oxygen gas which get rid of hydrogen without pan or blower. Hydrogen-Catalyst reaction produces natural convection by temperature gab. Using natural convection, Hydrogen get into the Submarine H2 eliminator.

Product Features

[Performance]

Specification

[Size]

- Square : 137 x 137 x 50/35cpsi (Cell per square inch) with a Steel Cartridge

- Square : 150 x 150 x 50/35cpsi (Cell per square inch) with a Steel Cartridge

Product Use

[Application]

- Submarines

- Nuclear Power Plants

[Reference]

- Ceracomb has supplied Hydrogen removal devices to 4 submarines of Indonesia.

- Delivered and contracted with the Ministry of National Defense for JANGBOGO III (60 devices - 3 submarines)

Company Profile

Ceracomb Co., Ltd.

Ceracomb Co., Ltd. has been producing and supplying ceramic honeycombs using ceramics extrusion molding technology. We have been

developing and supplying catalytic products for industrial hazardous gas eliminating, automobile exhaust gas purification, and filters for reducing soot. Moreover, the automobile particulate matter reduction device developed based on Ceracombs honeycomb and catalytic technology, is contributing greatly to the improvement of the fine dust / atmospheric environment which is becoming an issue in the 21st century.

Website : http://ceracomb.co.kr/english/

Advanced Safety and Durability

Equipped with over-pressure protection and an emergency shut-off system, this device prioritizes operational safety in demanding environments. Its double mechanical seal and polished stainless steel construction guarantee corrosion resistance and a long operational life, even under high ambient humidity (up to 90% RH). Designed to be easy to maintain, maintenance is required only once every quarter.

Intuitive Control and Efficient Performance

Controlling the device is streamlined with a digital touch display that offers adjustable flow rates and real-time monitoring. The integrated air-cooling and automatic lubrication systems support high efficiency and longevity, processing up to 500 liters per hour across compatible gases like hydrogen, nitrogen, and argon. The device fits seamlessly in industrial setups, with a compact, rectangular form and mirror finish for both aesthetics and practicality.

FAQ's of Hydrogen Removal Device:

Q: How does the Hydrogen Removal Device operate and what gases can it process?

A: This device uses advanced catalyst filtration to efficiently remove hydrogen and other impurities from compatible gases such as hydrogen, nitrogen, and argon. The process ensures high purity and reliability in industrial applications like metallurgy, chemical processing, and gas purification.Q: What safety systems are included in the device and how do they function?

A: The device features over-pressure protection and an emergency shut-off mechanism. These systems automatically respond to pressure fluctuations or operational anomalies, helping prevent accidents and ensuring safe operation even in high-pressure environments.Q: When should maintenance be performed on the Hydrogen Removal Device?

A: Routine maintenance is recommended every quarter to maintain optimal performance. This includes inspecting the pre-filtration system, lubrication mechanism, and checking for wear on critical components due to extended operation.Q: Where should the device be stored or installed for best performance?

A: Install the device in a dry, dust-free area with ambient humidity up to 90% RH, and within temperatures ranging from 10C to 60C. Its floor-mounted design requires a stable surface and proximity to electric power (220 V) for safe and continuous operation.Q: What is the process for adjusting the flow rate and monitoring operational status?

A: The device features a digital touch display control panel that allows users to set and adjust the flow rate as per their process requirements. The panel also provides real-time feedback on system performance, operational status, and alerts for maintenance needs.Q: What are the main benefits of using this device in industrial applications?

A: Key benefits include high efficiency, corrosion resistance, low noise (<65 dB), long operational life, ease of maintenance, and compatibility with multiple industrial gases. The integrated safety and filtration systems contribute to improved operational reliability and productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese