Drain master V - Auto drain trap with a motorized ball valve

Product Details:

- Motor Power 5-10 W (actuator)

- Drive Type Electric motor actuation

- Size 1/2 inch, 3/4 inch (custom sizes available)

- Lubricating System Maintenance Free / No lubrication required

- Features Zero air loss, fully automatic operation, timer-programmable, LED indication, manual test switch, compact design, easy installation

- Noise Level <70 dB(A)

- Surface Finish Smooth, corrosion-resistant finish

- Click to View more

Drain master V - Auto drain trap with a motorized ball valve Price And Quantity

- 5 Unit

Drain master V - Auto drain trap with a motorized ball valve Product Specifications

- Maintenance Free / No lubrication required

- Smooth, corrosion-resistant finish

- <70 dB(A)

- Valve available in 1/2 & 3/4 diameters

- Electric

- 5-10 W (actuator)

- Electric motor actuation

- 1/2 inch, 3/4 inch (custom sizes available)

- Zero air loss, fully automatic operation, timer-programmable, LED indication, manual test switch, compact design, easy installation

- Powder coated/Anodized

- 2.6 kg approx.

- Silver/Grey with black actuator

- Auto drain trap with a motorized ball valve

- Motorized ball valve with programmable timer

- Suitable for compressors up to 2000 CFM

- 10-15 W (typical)

- Automatic condensate drainage for air compressors, receivers, filters, aftercoolers, dryers, and drip legs

- Rectangular body with cylindrical valve section

- 195 x 105 x 135 mm approx.

- Corrosion resistant metal (typically stainless steel or anodized aluminum)

- 230V AC / 110V AC (as per model)

- Max. operating pressure up to 16 bar

Drain master V - Auto drain trap with a motorized ball valve Trade Information

- Incheon or Busan, South Korea

- Telegraphic Transfer (T/T)

- Export Standard Packing

Product Description

Detailed Images

Product Description

DRAINMASTER V is used for effective discharge of condensate under extremely low pressure such as in a vacuum

Working pressure 0.1bar - 1.8bar(abs)

Do not use this if exceeding the working pressure, for it can affect the sealing.

Product Usage

DRAIN MASTER V needs clean air or gas between 4 bar and 8 bar for discharge of condensate, and control air, residual air, gas etc. within the housing may leak into the vacuum system. Thus, it should be applied to a system in which such amount of air or gas cause no problem (e.g. formation of explosive gas) in terms of technologies, production processes, and safety.

In general, DRAIN MASTER V is connected to the condensate lead-in line and requires installation of a balance(equal) air line if a large quantity of condensate is generated.

Product Features

The level sensor within the housing detects the level of condensate, and the condensate lead-in line is blocked and pressure is formed in the housing if it reaches the top dead point by supplying control air or gas via opening of a solenoid valve . The pressure formed within the housing discharges condensate when the motorized ball valve is operated. After condensate is completely discharged, the solenoid valve blocks control air or gas to allow inflow of condensate.

Product Installation

A regulator should be installed to maintain pressure for discharge of condensate between 4 bar and 8 bar.

Discharge of condensate is impossible if the pressure is below 4 bar or the valve remains opened or the valve for the vacuum system remains closed if above 8 bar.

Notice! A small amount of control air is discharged into the air when a valve is opened.

A small amount of control air or gas (nearly 1 liter) is discharged into the air when a valve is opened. If explosive or hazardous gas is used for controlling, the pipe for the gas should be connected to a gas-collection tank.

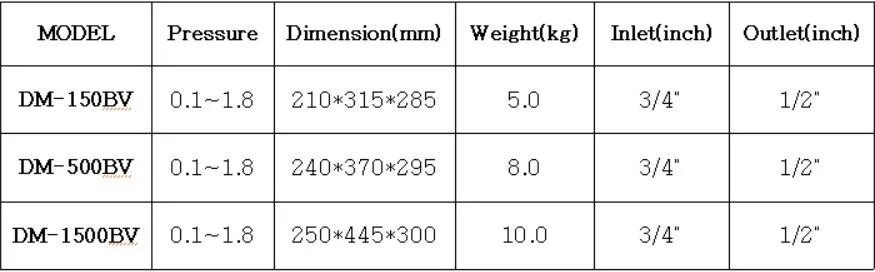

Product Model

Company Information

PEOPLE oriented technology,

NATURE friendly company.

Technology to the first person. To think of the environment.

We have been worked for efficient treatment of condensation water generated in Air Compressor System. We are producing Auto drain trap that is an economical and reliable condensate discharger, Oil-water separator that is processing unit for condensate contaminated by oil with advanced technique and know-how.

However, energy and environment are giving big influence in enterprise activity in 21th century industrial field, and it is considered that frugality of expensive compressed air and processing for contaminated condensate are helpful to solve these troubleshooting Forward, we will do our best to answer customer's cheering by developing product helpful for enterprise activity.

Contact Us

Company Name : EnE System Co., Ltd.

Website : http://www.enesystem.com

Tel : 070-4027-3673

Effortless Condensate Drainage

Drain Master V offers fully automatic operation with programmable timers, ensuring optimal condensate removal from compressors, filters, and dryers. The zero-air-loss design maximizes energy efficiency and reliability. Its compact, corrosion-resistant construction is suited for demanding industrial environments, supporting easy installation and minimal maintenance.

Smart Actuator and Control Panel

The actuator is powered by an electric motor and incorporates manual override and test features for fail-safe operation. Users benefit from real-time drain status updates via an LCD/LED panel directly on the actuator body, making monitoring and adjustments intuitive and straightforward.

FAQs of Drain master V - Auto drain trap with a motorized ball valve:

Q: How do I install the Drain Master V Auto Drain Trap?

A: The unit is designed for wall or inline mounting and comes with BSP/NPT threaded end connections, making it compatible with standard piping. Installation is straightforward: secure the drain trap at the desired location, connect the threaded ends, and plug in the power supply. A 1.5-meter power cable is included for convenience.Q: What makes the Drain Master V suitable for harsh environments?

A: With its IP65 actuator housing, corrosion-resistant powder-coated or anodized metal body, and smooth surface finish, the Drain Master V is well protected against dust, moisture, and chemical exposure. This makes it ideal for industrial settings with fluctuating temperatures and demanding conditions.Q: When and how can I program the drain and off times?

A: Programming is performed directly from the integrated control panel, which features clear LCD/LED indicators. Users can set customizable drain times (0.5 to 10 seconds) and OFF intervals (1 to 60 minutes) to match varying condensate loads and optimize performance.Q: Where is the control panel located and what does it display?

A: The control panel is mounted on the actuator body for easy access. It displays operational statuses, drain cycle setting, and error notifications via LCD/LED indications, allowing users to monitor real-time operation and make adjustments as needed.Q: What maintenance is required and how often?

A: The Drain Master V is designed for minimal maintenance due to its self-lubricating motorized ball valve and easy-access service design. Routine inspection is recommended, but service intervals are infrequent, and no lubrication is required.Q: How does the manual override and test feature work for failsafe operation?

A: The manual override and test functions on the actuator body allow users to manually activate the valve and verify system operation when needed. This ensures uninterrupted drainage even in case of electrical or programming issues.Q: What are the main benefits of using the Drain Master V in my system?

A: The unit provides automatic, zero-air-loss drainage, enhancing system efficiency and reliability. Its programmable features, robust construction, and easy installation make it an ideal choice for diverse industrial applications, reducing manual intervention and operating costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese