UNITEST M1 Universal Testing Machine

Product Details:

- Usage & Applications Tensile, Compression, Bending, Shear Tests

- Capacity Up to 100 kN

- Lubricating System Centralized Lubrication

- Motor Power 1 HP

- Noise Level <65 dB

- Size Standard Configuration

- Surface Finish Smooth

- Click to View more

X

UNITEST M1 Universal Testing Machine Price And Quantity

- 1 Set

UNITEST M1 Universal Testing Machine Product Specifications

- Centralized Lubrication

- <65 dB

- 1 HP

- Electric

- Blue-Grey

- Vertical Frame

- Tensile, Compression, Bending, Shear Tests

- Electro-Mechanical Drive

- Up to 100 kN

- Hydraulic, up to 250kN

- Universal Testing Machine

- Hydraulic Loading, Microprocessor-Based Technology

- 220-240 V AC

- Approx. 1200 kg

- Max specimen dia 40 mm

- Digital display, Overload protection, Automatic data recording

- Standard Configuration

- Powder Coated

- Mild Steel Body

- 2 kW

- Smooth

- 1810 x 850 x 2200 mm

UNITEST M1 Universal Testing Machine Trade Information

- Busan Port

- Telegraphic Transfer (T/T)

- 30 Days

- Wooden Box

- ISO 9001, CE

Product Description

Universal Testing Machine is a representative test equipment for physical properties. It is capable of measuring load, strength, elongation of products or materials such as rubber,film,plastic,metal etc.Product Specification

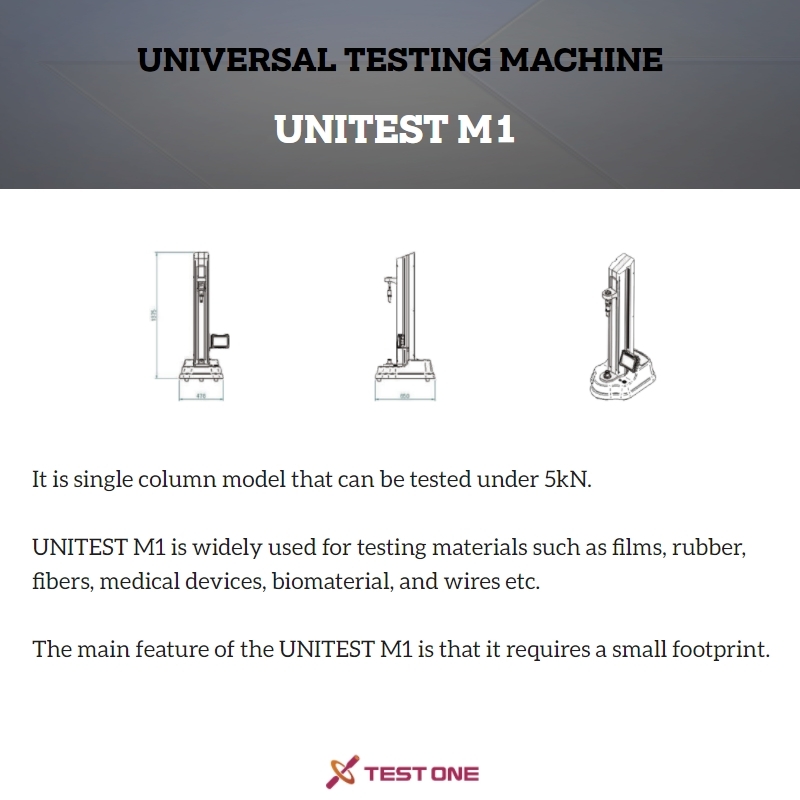

- Frame Load Capacity (Max.) : 5kN

- Main Load Cell : 5kN

- Load Range : 50 (kgf) (Up to 4-step conversion)

- Column Type : Single Column

- Load Accurancy : Less than 0.5%

- Crosshead Speed Range : 0.01 -500mm/min

- Load Resolution : 1/50,000

- Machine Controller : Touch Type Servo Controller(Position Control Type)

- Test Category : Tensile, Tear, Peel, Compression, Bending, Repeat, etc.

- Dimensions : 478x650x1375(H), 82kg

- Main Power : AC 220V 2P, 50/60

Features-

- It is single column model that can be tested under 5kN.

- UNITEST M1 is widely used for testing materials such as films, rubber, fibers, medical devices, biomaterial, and wires etc.

- The main feature of the UNITEST M1 is that it requires a small footprint

Advanced Testing Performance

The UNITEST M1 Universal Testing Machine harnesses microprocessor-based, computerized control to deliver accurate and reproducible material testing. With a wide testing speed range, high load and displacement resolution, and electronic safety features, it is suitable for rigorous tensile, compression, bending, and shear evaluations. Interchangeable grips accommodate various specimen types, providing versatile usage across multiple industries.

Comprehensive Safety and Data Management

Engineered with overload protection, emergency stop, and electronic stroke limit switches, the M1 prioritizes operator safety and equipment integrity. Its data acquisition system allows real-time monitoring, recording, and analysis, while accessories like extensometer and printer ensure comprehensive documentation for every test.

Built for Reliability and Versatility

Constructed from powder-coated mild steel and equipped with a robust hydraulic system, the M1 provides lasting durability and stable performance. Its centralized lubrication, low noise level, and smooth finish make it ideal for demanding laboratory or industrial environments, with full support for different test samples and analysis needs.

FAQs of UNITEST M1 Universal Testing Machine:

Q: How does the computerized control and data acquisition system benefit testing with the UNITEST M1?

A: The computerized control offers precise parameter setting, real-time monitoring, and automatic data recording. This ensures high accuracy and repeatability of tensile, compression, bending, and shear tests, while simplifying data analysis and reporting through supplied software and printer accessories.Q: What types of specimens and tests can be conducted using the M1 Universal Testing Machine?

A: The M1 supports specimens with diameters ranging from 10 mm to 40 mm and is engineered for tensile, compression, bending, and shear testing. Interchangeable grips provide flexibility for different material forms, enhancing its utility in diverse testing applications.Q: When is the right time to perform maintenance on the M1, and what does the process involve?

A: Routine maintenance should be conducted according to manufacturer guidelines or following intensive usage. The centralized lubrication system simplifies upkeep, and regular checks on electronic limits, grips, and hydraulic components ensure optimal performance and safety.Q: Where can the M1 Universal Testing Machine be installed for optimal operation?

A: The M1 is suitable for laboratory or industrial environments within operating conditions of 10C to 45C and 20%80% non-condensing humidity. Its robust design and moderate dimensions make it adaptable for standard test room installations.Q: What safety features are included in the UNITEST M1 and how do they protect users?

A: Safety is ensured through overload protection, a responsive emergency stop, and electronic limit switches that prevent crosshead overtravel. These features safeguard both users and equipment during operation.Q: How do users benefit from the machines interchangeable grips and extensive accessory compatibility?

A: Interchangeable grips allow rapid adaptation to various sample shapes and sizes, making the M1 versatile for broad test requirements. Accessories like extensometers, printers, and data analysis software further streamline testing and results reporting processes.Q: What are the advantages of hydraulic loading and microprocessor technology in the M1?

A: Hydraulic loading provides stable, high-capacity force application (up to 100 kN), while microprocessor-based technology ensures reliable control, precise measurement, and smooth automation throughout the entire testing procedure.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese