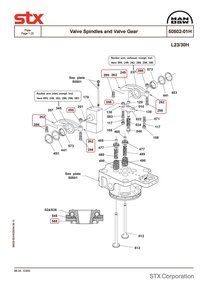

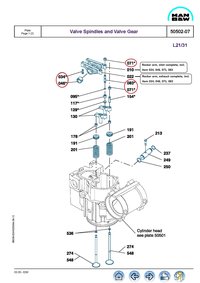

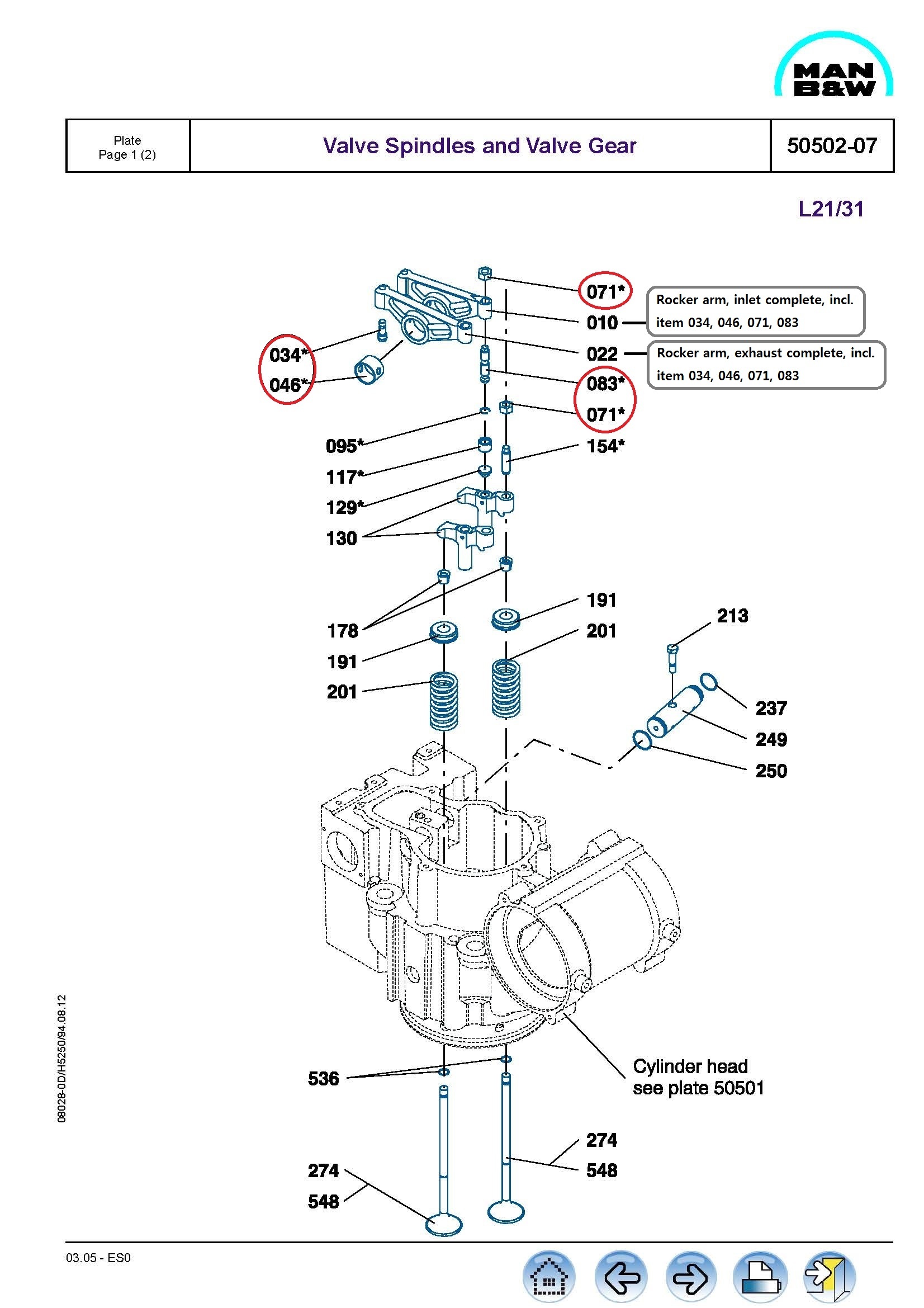

ROCKER ARM COMPLETS

Product Details:

- Surface Finish Machined

- Size Custom/OEM as per vehicle specification

- Diameter Standard/Custom as per application

- Features High Strength, Wear Resistant, Precision Machined

- Lubricating System Engine Splash / Forced Lubrication

- Drive Type Mechanical Driven

- Shape Curved Lever

- Click to View more

ROCKER ARM COMPLETS Price And Quantity

- 100 Unit

ROCKER ARM COMPLETS Product Specifications

- Suitable for single or twin cylinder

- Precision Forged

- Curved Lever

- Low

- Silver Grey

- Automobile Engine Valve Train Systems

- Engine Driven

- Rocker Arm Complets

- High Strength, Wear Resistant, Precision Machined

- Mechanical Driven

- Engine Splash / Forced Lubrication

- Custom/OEM as per vehicle specification

- Machined

- Approx. 120-250 grams (varies by model)

- Alloy Steel

- Standard OEM Size

- Phosphated / Shot Peened

- Standard/Custom as per application

Product Description

Product Description

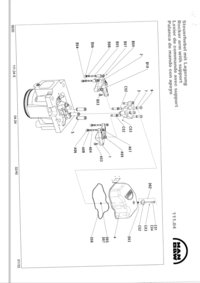

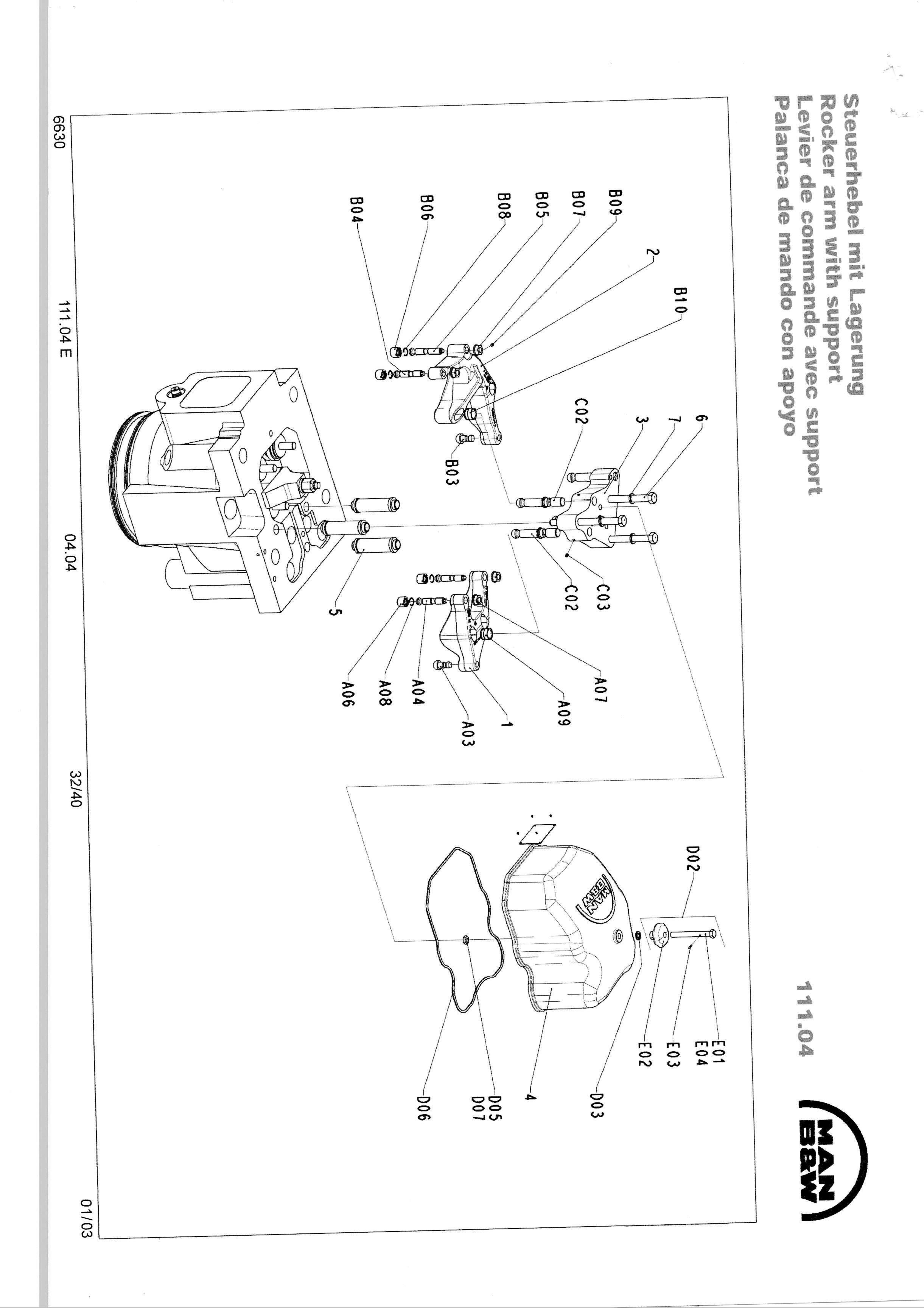

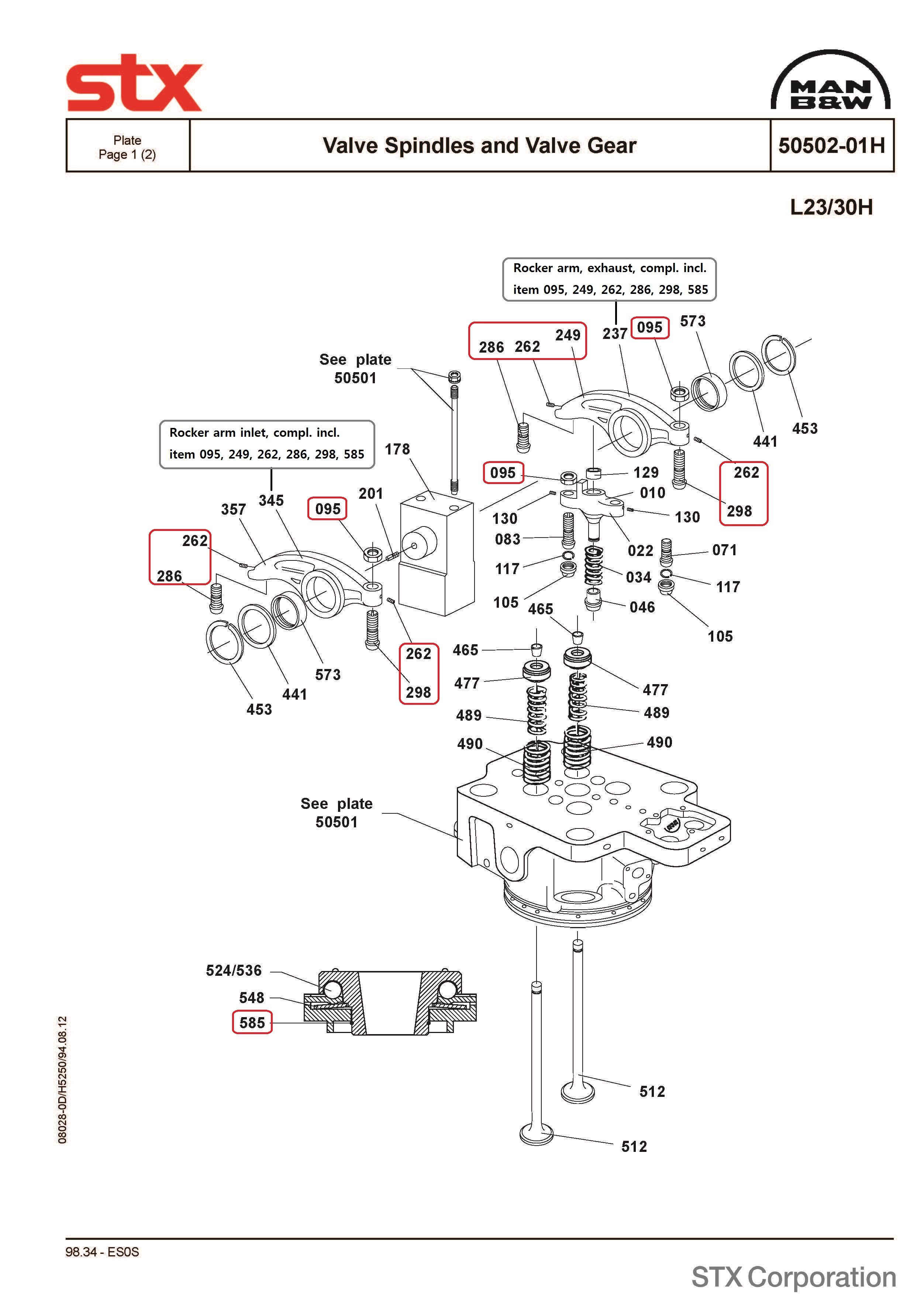

Rocker Arm Complets is an oscillating lever that convenys radial movement from the cam lobe into linear movement at the poppet valve to open it.

We have been make rocker arm complets that recognized in a number of repair company for several years.

By the way, we can provide as a single unit or assembly of state if you require customers.

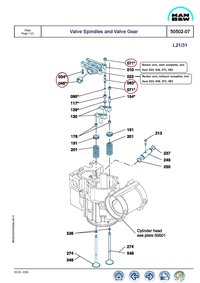

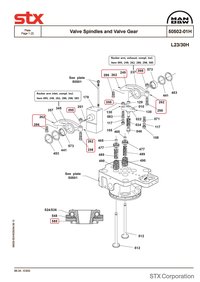

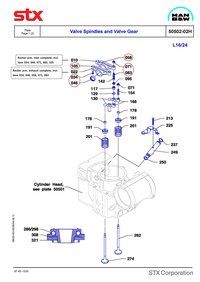

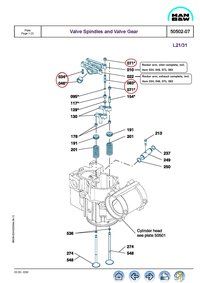

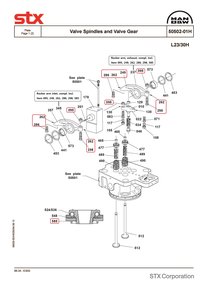

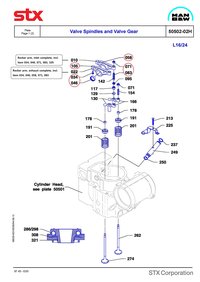

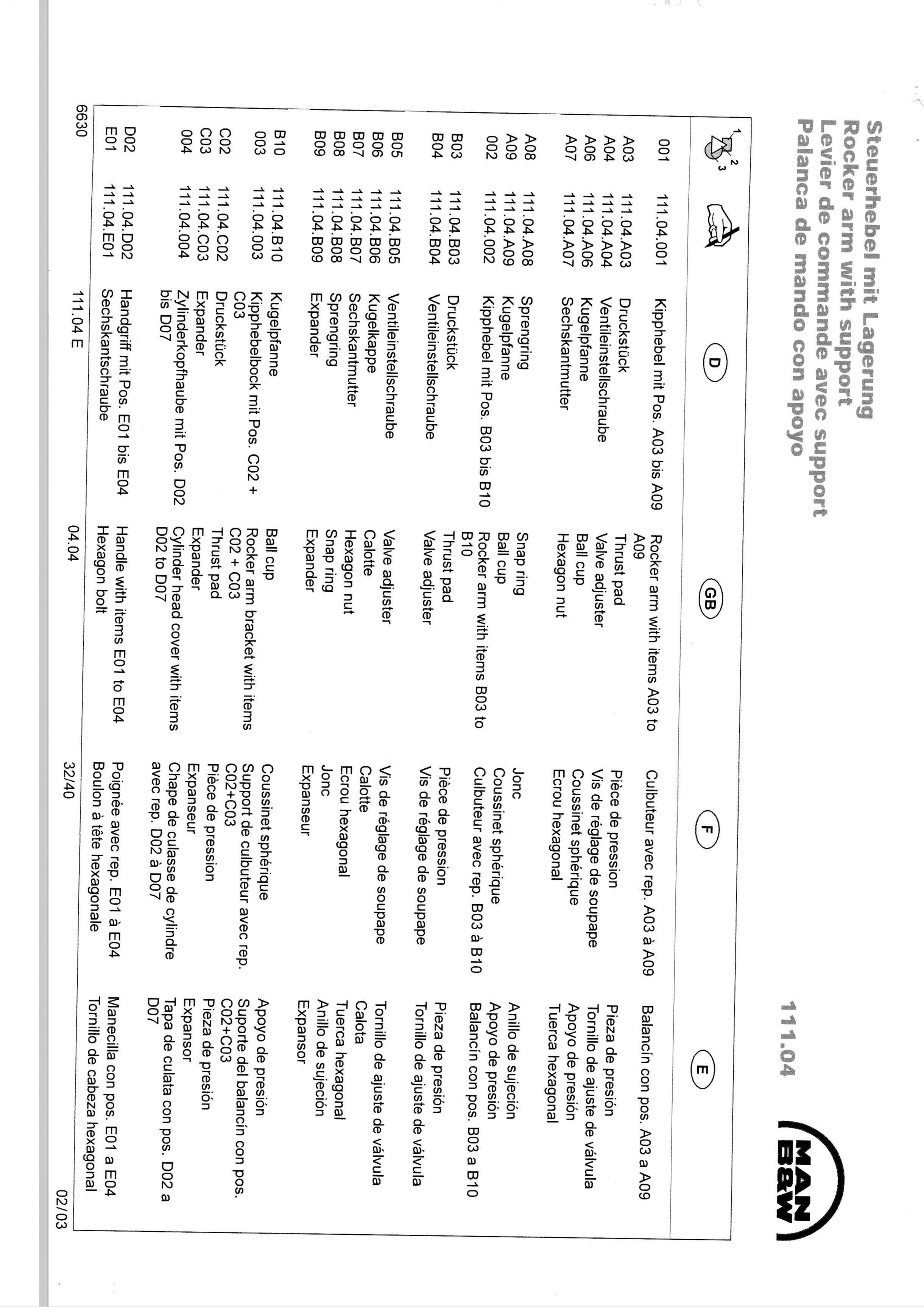

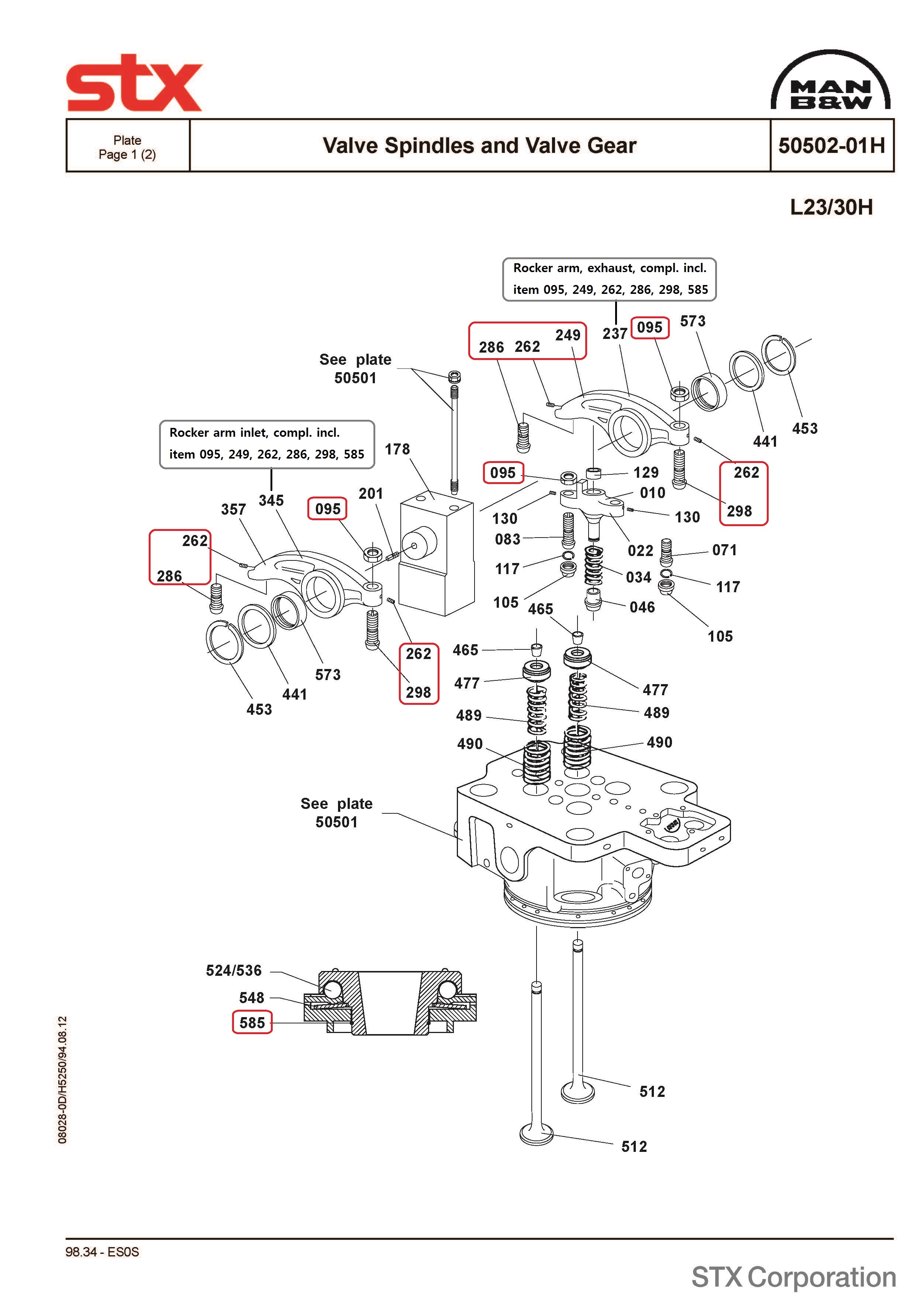

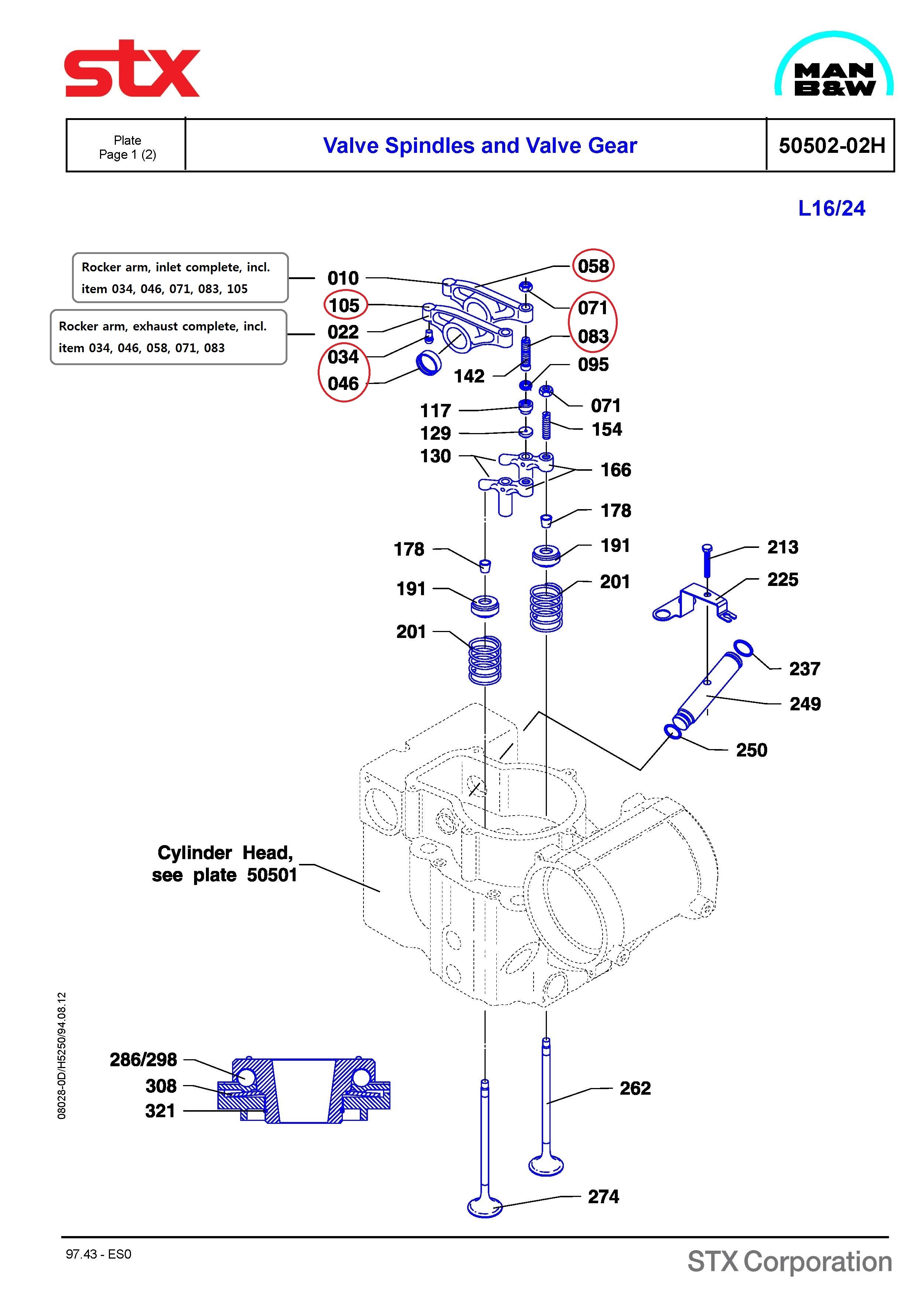

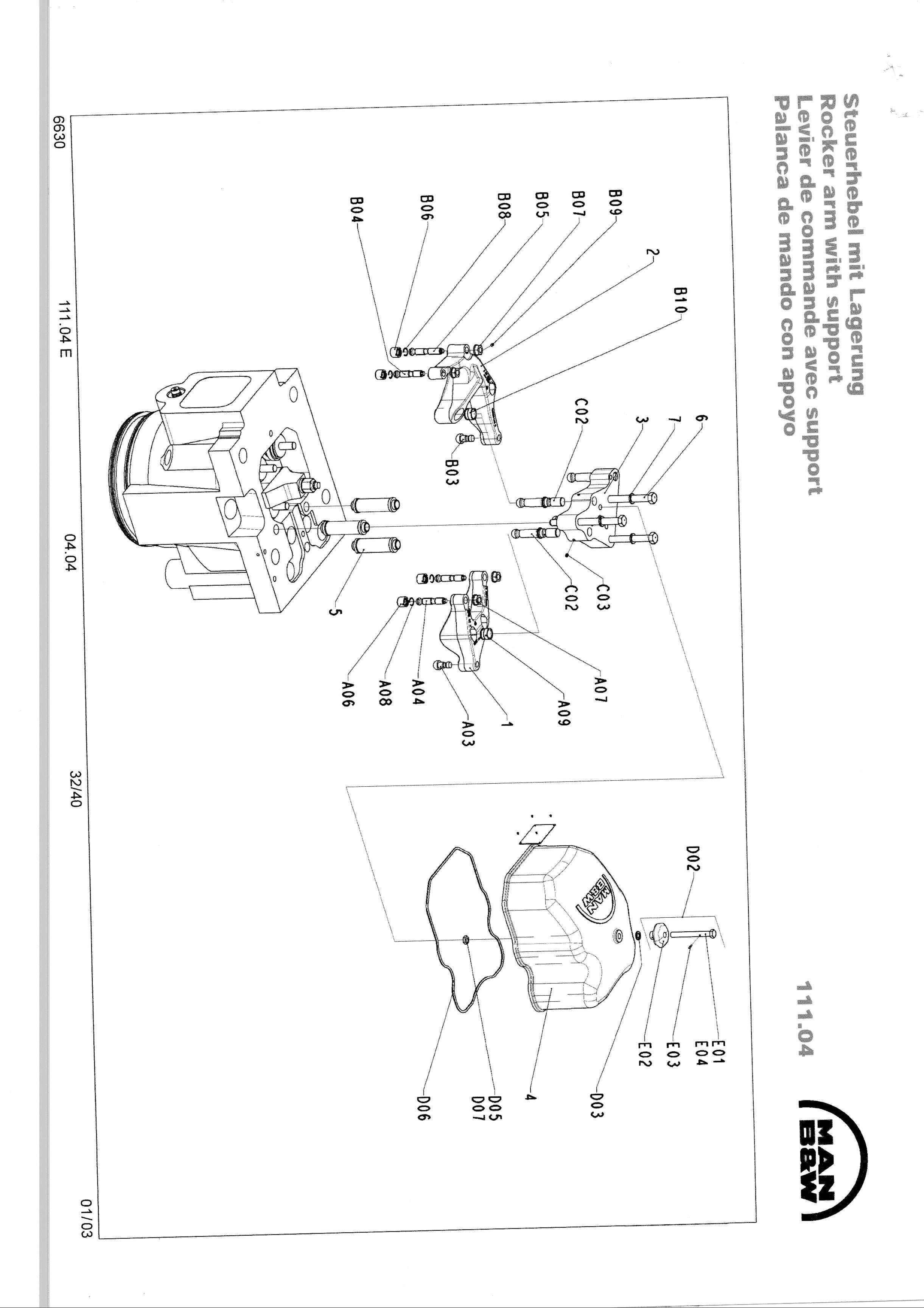

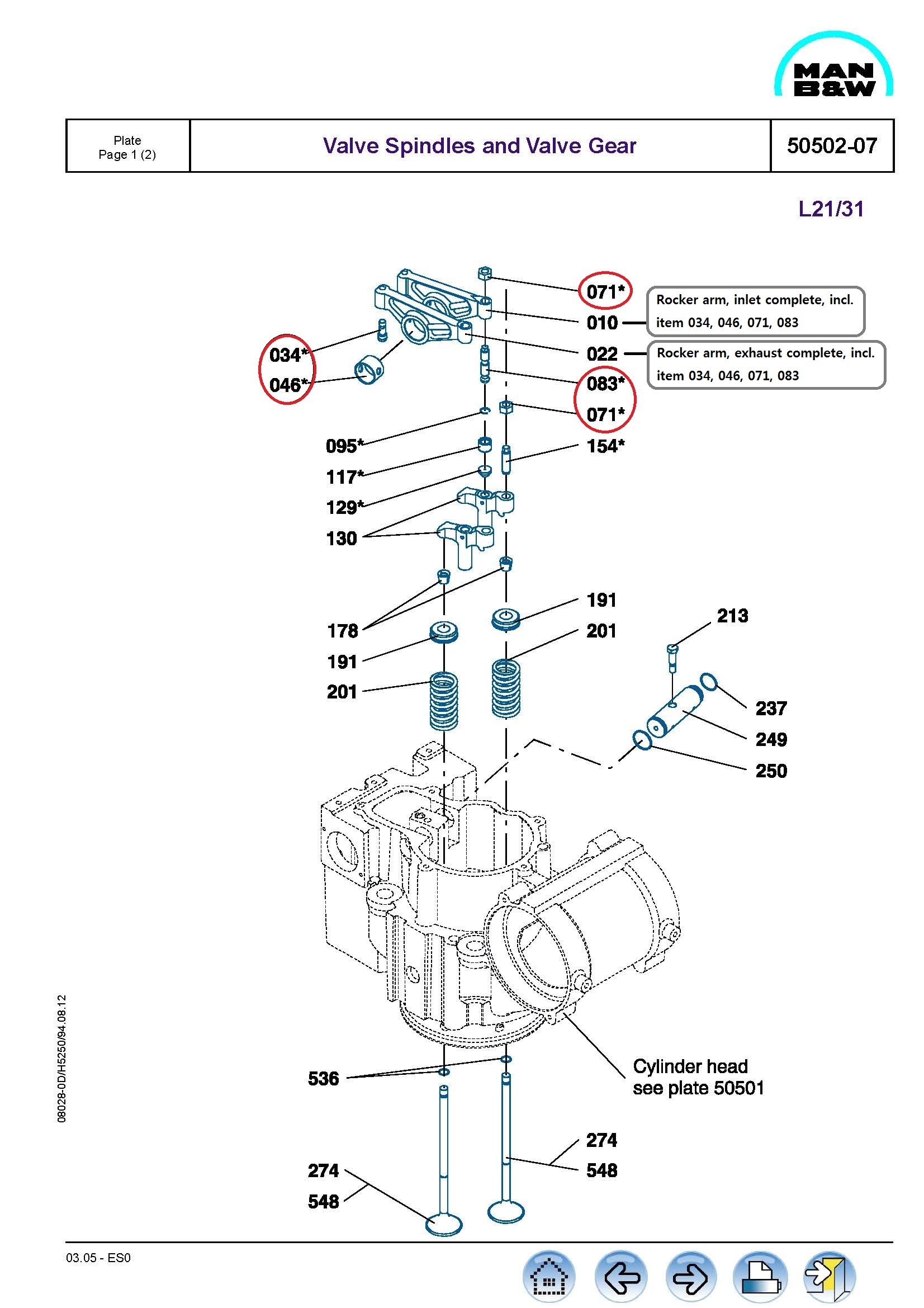

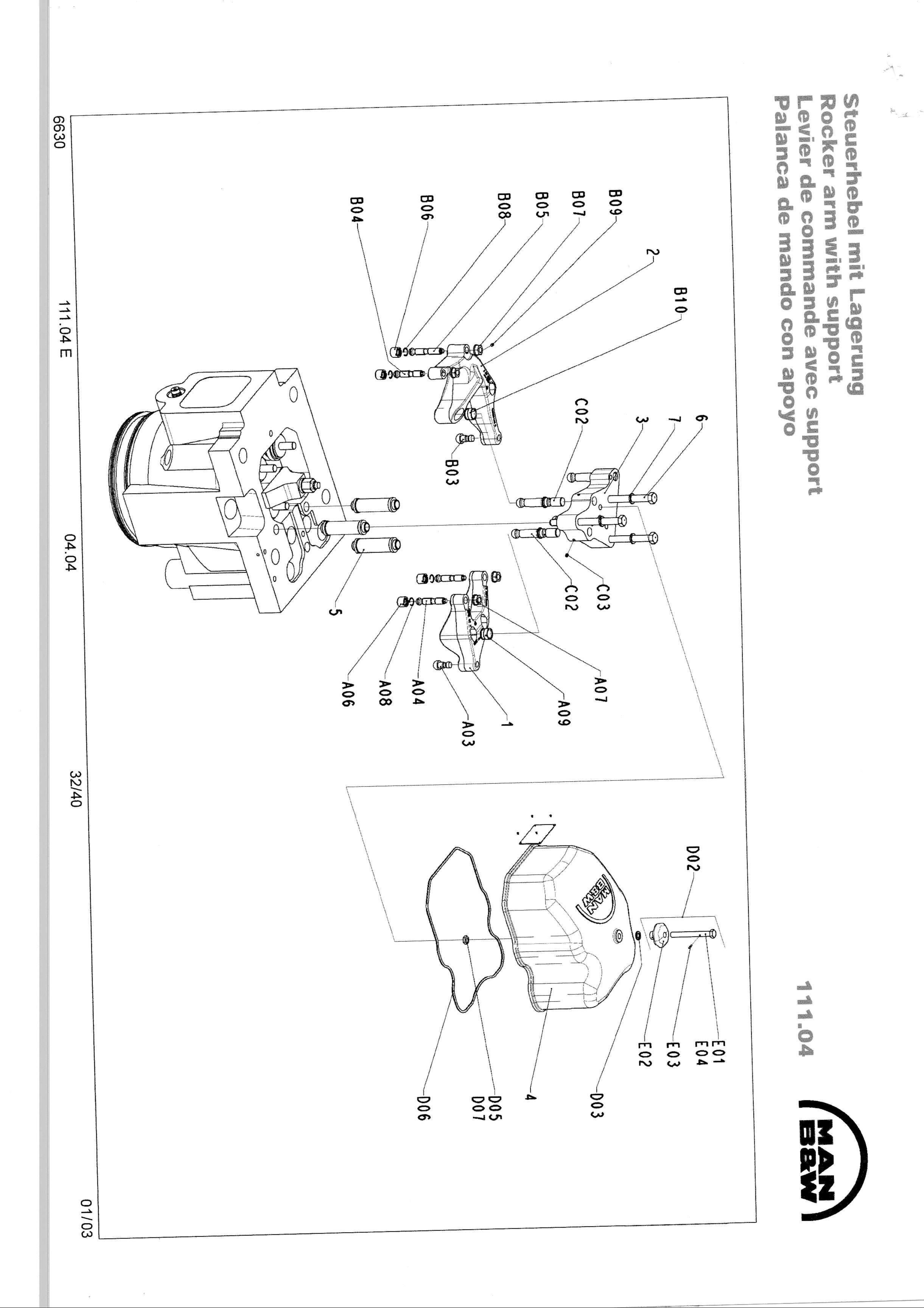

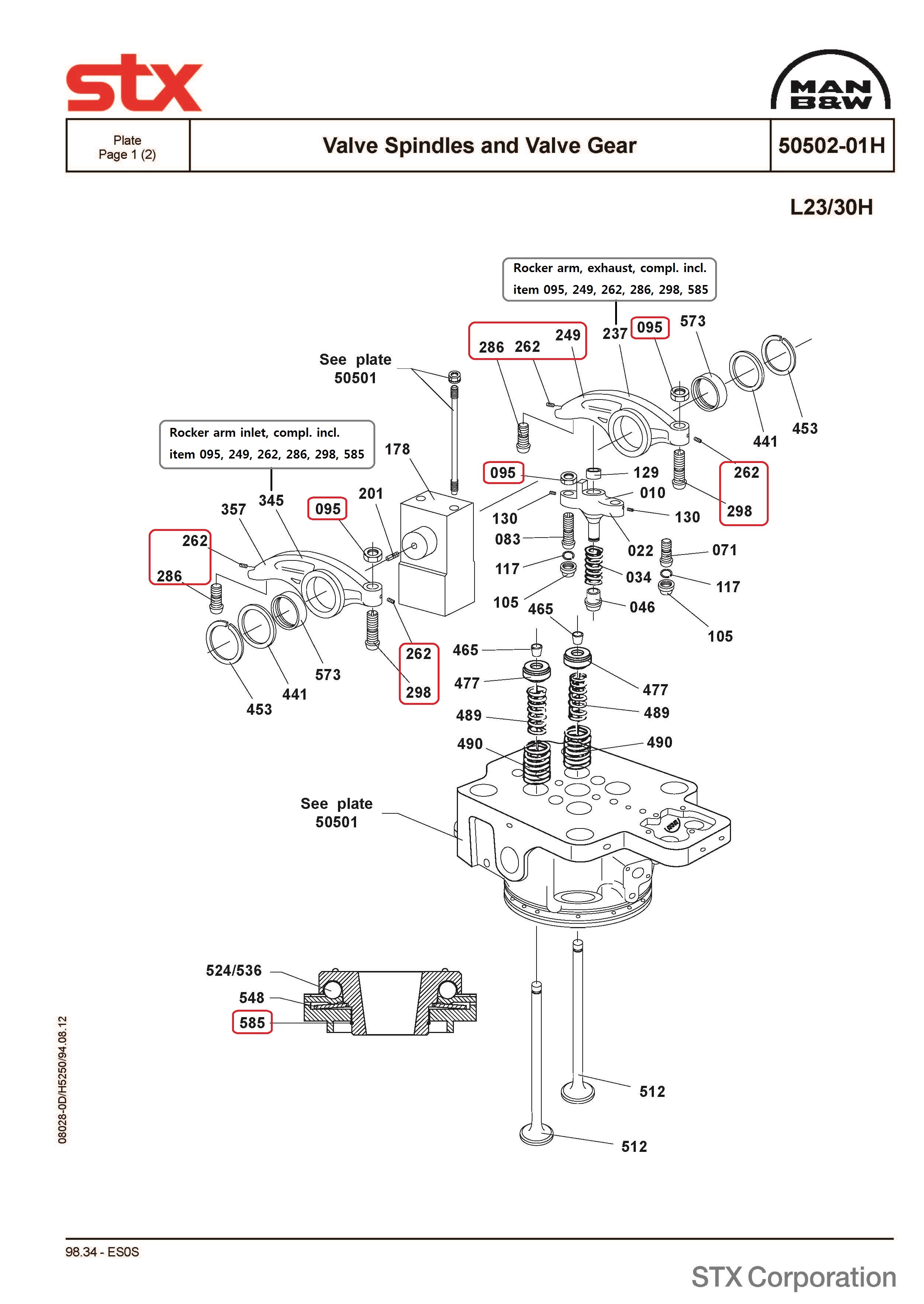

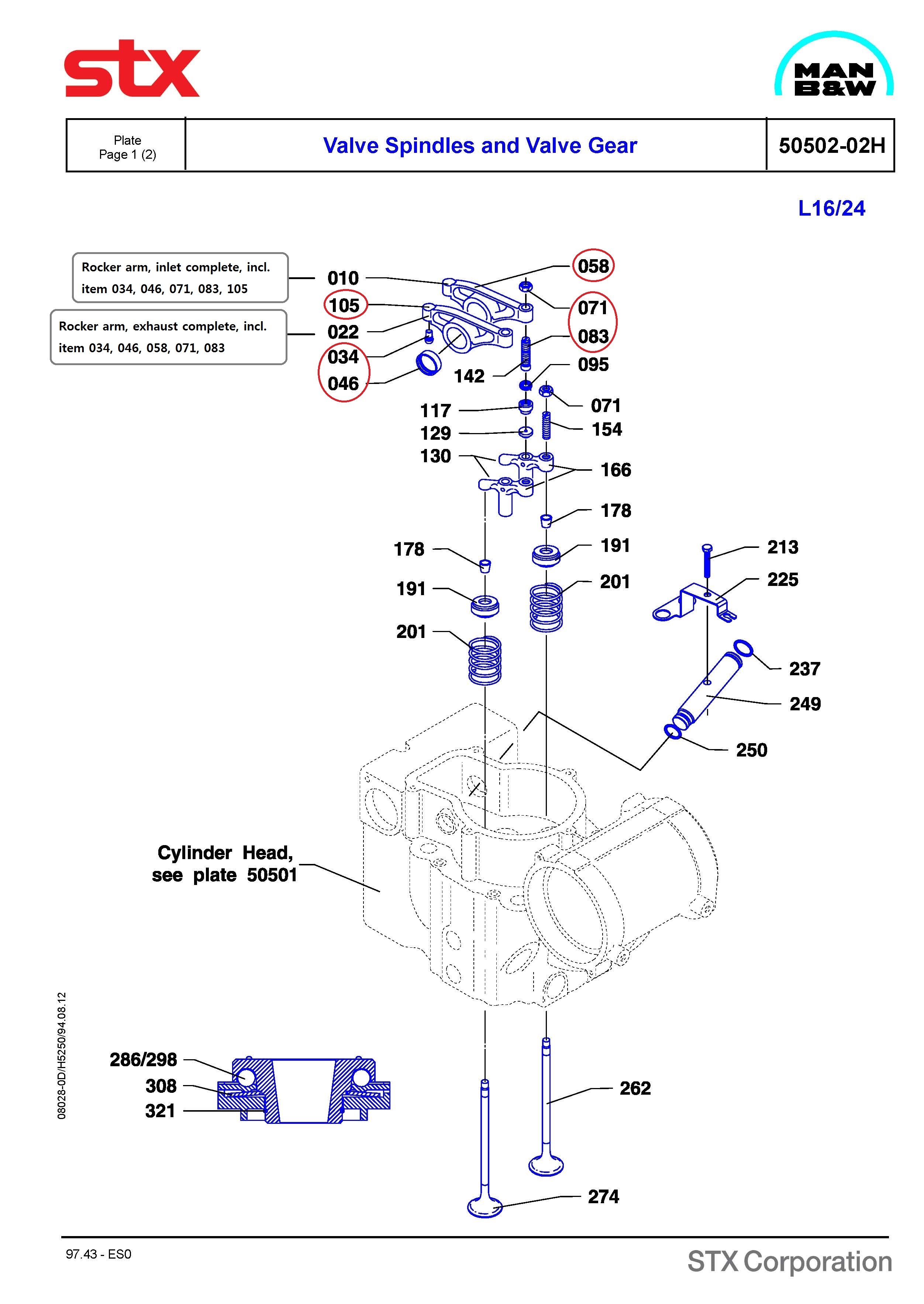

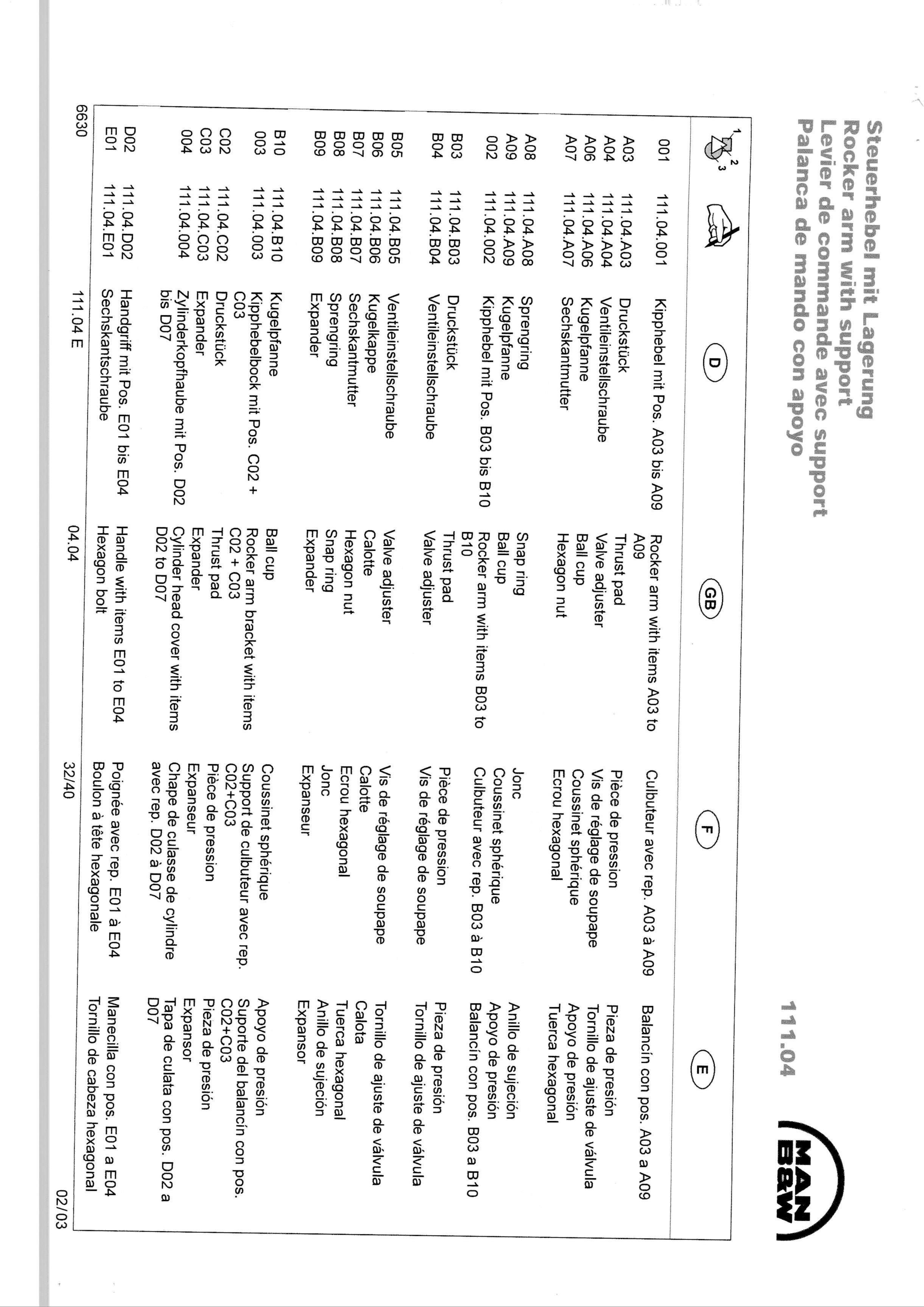

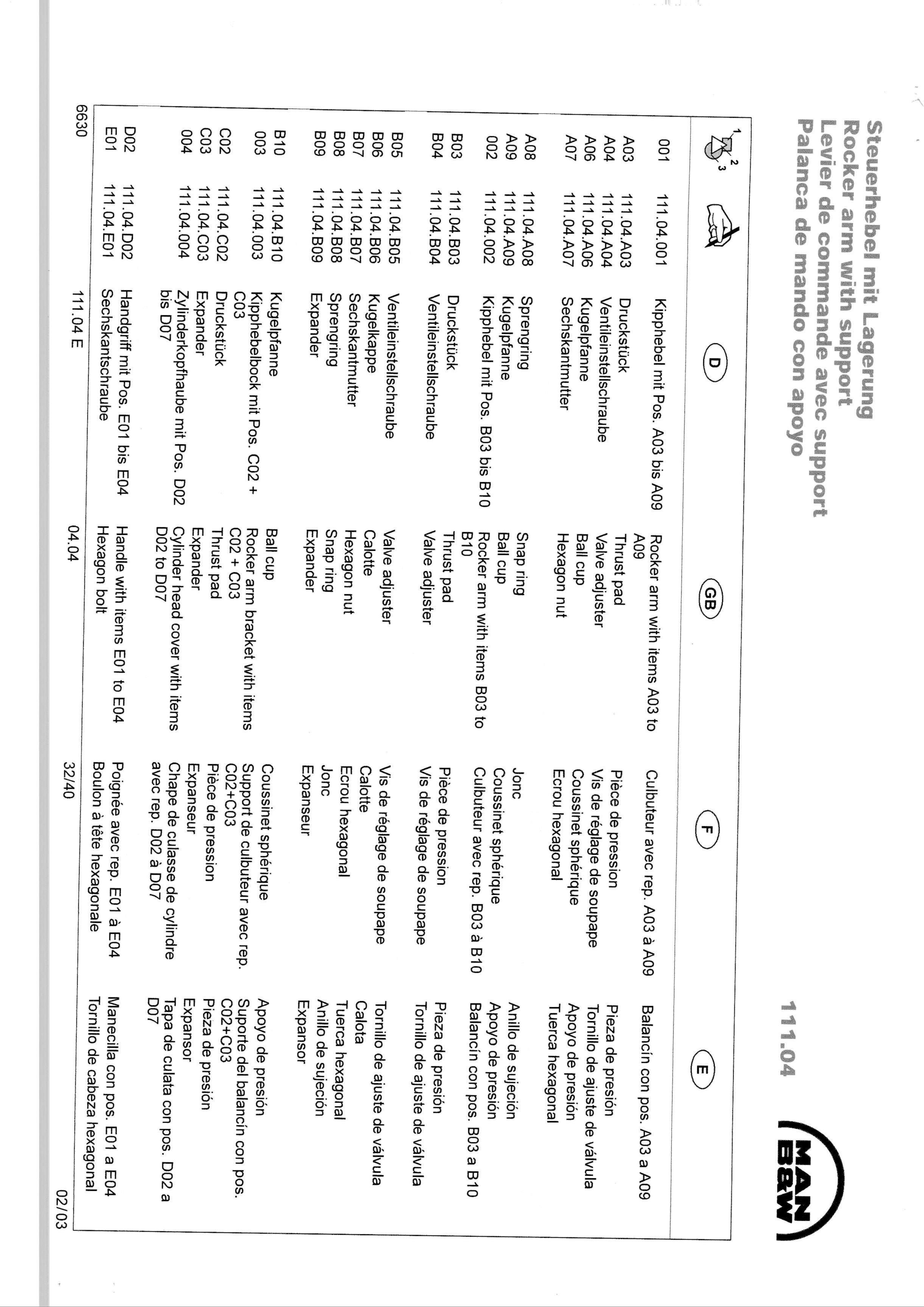

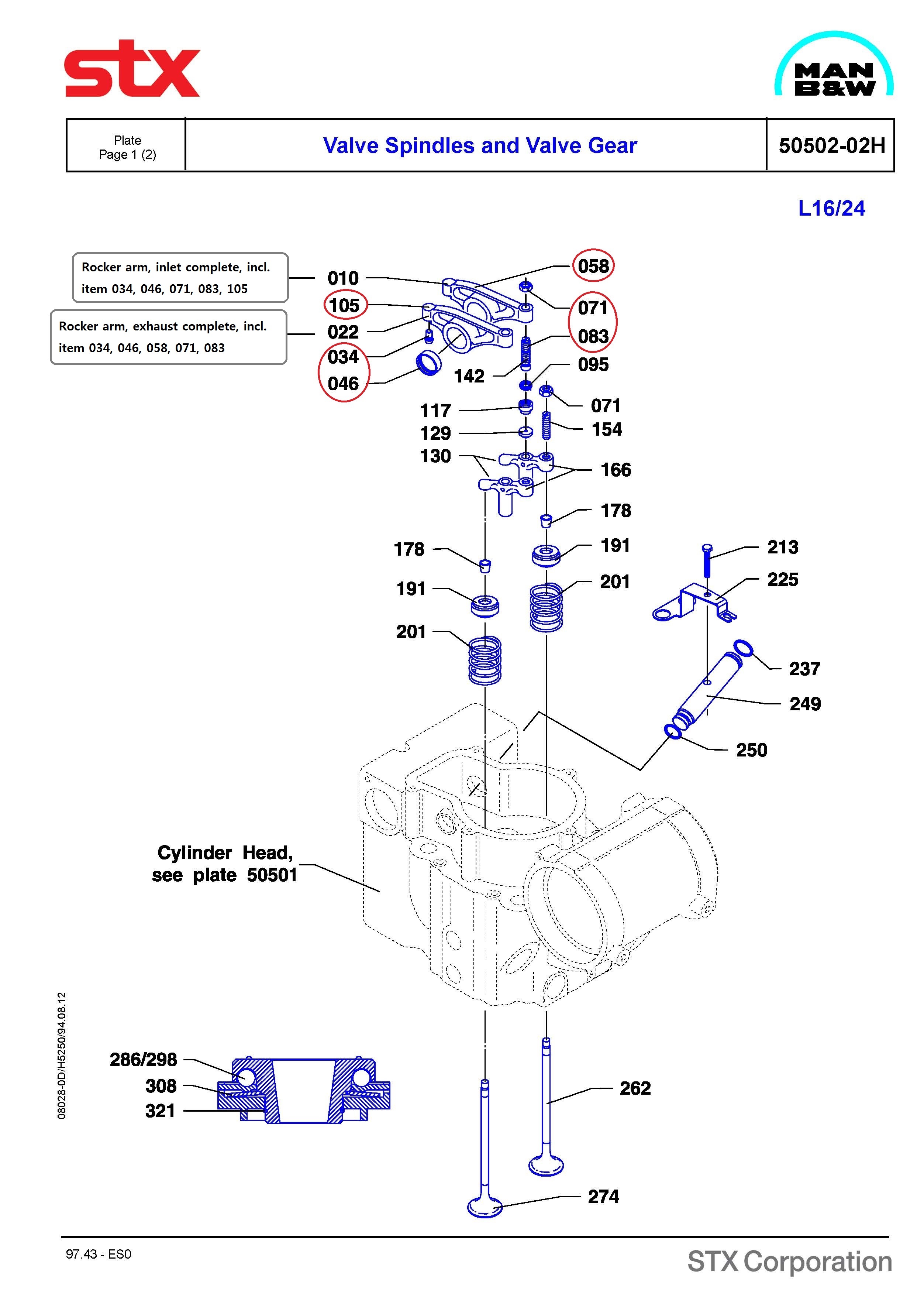

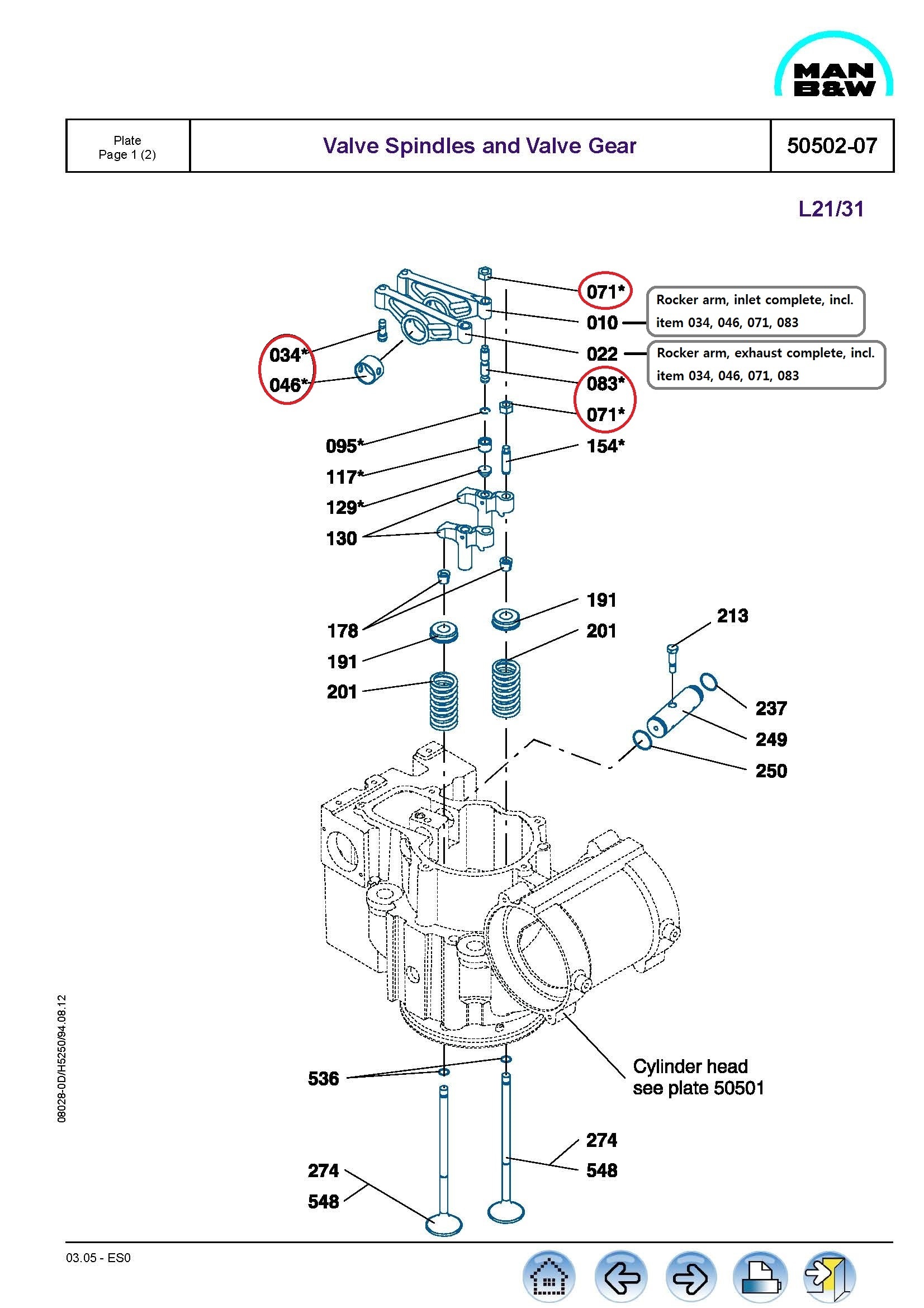

We are able to supply MAM B&W type L16/24, L21/31, L23/30, L23/30H, L27/38, L+V28/32, L32/40CD.

Our Company

BK DIESEL concentrates on the production of core parts of the engines for land and marine vehicles and devotes itself to the business as the engine parts specializing enterprise with the challenge and passion since its establishment in 2011 and it will focus on the continuous development of products.

We know the importance of correct and fast delivery and over the years have built up very good relations with our suppliers, thus always ensuring you the best possible prices and the opportunity tho order from different makers at one place.

Robust Compatibility Across Vehicle Types

Designed for seamless integration, the ROCKER ARM COMPLET is available for a wide array of two-wheeler and four-wheeler models. Whether you require standard or custom OEM sizing, these rocker arms ensure accurate fitment and optimal performance, making them an effective solution for diverse vehicle specifications.

Superior Engineering and Durable Materials

Precision forged from high-grade alloy steel and heat treated for enhanced hardness (HRC 55-62), the ROCKER ARM COMPLET provides long-lasting strength and wear resistance. Each unit is engineered with a machined and phosphated or shot-peened surface finish, supporting effective lubrication and reducing friction for quieter operation.

Hassle-Free Installation and Minimal Maintenance

Installation is straightforward due to its direct OEM replacement compatibility. The product's robust construction and corrosion-resistant packaging minimize maintenance, with only periodic engine inspection recommended. This ensures reliable performance throughout its service life with minimal downtime.

FAQ's of ROCKER ARM COMPLETS:

Q: How do I install a ROCKER ARM COMPLET on my two-wheeler or four-wheeler?

A: Installation is straightforward, as the rocker arm is designed for direct OEM replacement. Simply refer to your vehicle's service manual for specific instructions, ensuring proper alignment and securing as per manufacturer guidelines. Professional fitting is recommended for optimal results.Q: What is the benefit of choosing die-forged and heat-treated rocker arms?

A: Die forging and heat treatment processes significantly enhance the strength, toughness, and hardness (HRC 55-62) of the rocker arm. These features ensure a longer lifespan, reduced wear, and sustained performance even under high-temperature operating conditions up to 180C.Q: When should I perform maintenance or inspection on my rocker arm?

A: The ROCKER ARM COMPLET requires minimal maintenance. However, it is advisable to conduct periodic engine inspections according to your vehicle manufacturer's recommendations to ensure optimal functioning and address any signs of wear promptly.Q: Where can I use these rocker arms, and are they suitable for custom applications?

A: These rocker arms are intended for use in automobile engine valve train systems and are compatible with both single and twin cylinder configurations. Custom and OEM sizing is available to match specific vehicle requirements, making them suitable for a wide variety of automotive applications.Q: What packaging options are provided to ensure product quality during transport?

A: ROCKER ARM COMPLETs are available in both bulk and individual packaging. Each packing method incorporates anti-rust protection to preserve quality and prevent corrosion during storage and transit.Q: How does the surface treatment enhance the performance of the rocker arm?

A: The rocker arms undergo phosphating or shot peening, followed by precision machining, which enhances their resistance to corrosion and surface fatigue. This treatment helps maintain low noise levels, efficient lubrication, and consistent mechanical performance over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese