TIRE(Wheel) and Crawler type EXCAVATOR Swing reduction

500 USD ($)/Unit

Product Details:

- Shape Cylindrical Gear Housing

- Size Standard OEM/Custom Sizes

- Lubricating System Integrated with Sealed Oil Bath

- Noise Level 80 dB

- Usage & Applications Excavators, Construction Machinery

- Features High Torque, Compact Design, Maintenance-friendly, Shock Resistant

- Drive Type Planetary Gear Drive

- Click to View more

X

TIRE(Wheel) and Crawler type EXCAVATOR Swing reduction Price And Quantity

- 1 Unit

- 500 USD ($)/Unit

TIRE(Wheel) and Crawler type EXCAVATOR Swing reduction Product Specifications

- Hydraulic

- Polished, Painted, or Powder Coated

- High Torque, Compact Design, Maintenance-friendly, Shock Resistant

- 230-690 mm (Model Dependent)

- Load Capacity up to 20 tons

- Precision Gear Machining

- Excavators, Construction Machinery

- Black / Grey / Custom

- 110-230 kg (Depending on model)

- 11-45 kW (depends on configuration)

- Depends on model (Example: 690mm x 530mm x 480mm)

- 80 dB

- Varies per model, typically 11-45 kW

- Planetary Gear Drive

- TIRE (Wheel) and Crawler type Excavator Swing Reduction Unit

- 21-35 MPa (Operational Hydraulic Pressure)

- Integrated with Sealed Oil Bath

- Not Applicable (Hydraulic Drive)

- High-strength Alloy Steel

- Standard OEM/Custom Sizes

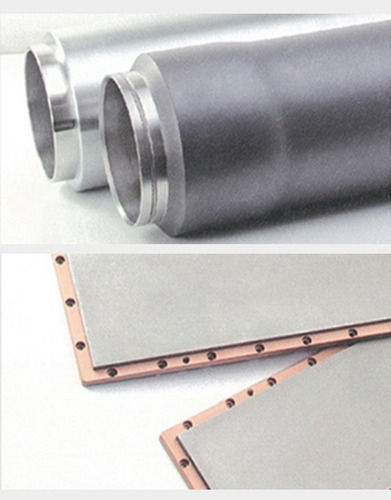

- Cylindrical Gear Housing

- Heat Treated, Anti-corrosion Coated

Product Description

Product Description

TIRE(Wheel) and Crawler type EXCAVATOR Swing reduction parts such as Swing Reduction Gear Assy including Carrier Assy, Planet Gear, Sun Gear, Pin, Drive shaft, Ring gear, Oil Seal, Bearing and related

Product Features

Raw material should be over FD60, Excellent performance for Gear without any defect on the surface with fine tolerance, Stable heating treatment, Angle and working pressure without backlash, Wear abrasion with durability, Exact producing process, 3D visual inspection, Qualified quality control system, Use exact tooling for producing per every items

For the customer more satisfaction, we always do consider below 3points to get our vision with partner

QUALITY; 1ST Qualified material, Field testing before using, Special compounded material

PRICE; Market research to get exact solution, Q.DAS system to saving cost, Minimize waste for environment

SERVICE; Full technical support, On time delivery by reasonable shipment charge, Update new technology

For the customer more satisfaction, we always do consider below 3points to get our vision with partner

QUALITY; 1ST Qualified material, Field testing before using, Special compounded material

PRICE; Market research to get exact solution, Q.DAS system to saving cost, Minimize waste for environment

SERVICE; Full technical support, On time delivery by reasonable shipment charge, Update new technology

Product Use

TIRE(WHEEL), CRAWLER TYPE EXCAVATOR SPARE PARTS(CORE PARTS)

Our Company

Dongbu Hydraulic parts is a spare part manufacture of earthmoving equipment since 1987. Also, we are 1st one, who has developed Hub axle and Transmission part of Tire(Wheel) type excavator in Korea.

Our main products are HUB AXLE, SWING, TRAVEL REDUCTION, TRANSMISSION, HYDRAULIC PUMP, SEALS and some related parts for heavy equipment since company foundation. Through continuous development and quality improvement, we were able to gain trust from customers and become the top company in Korea.

Thanks for your visiting our site and welcome your enquiries.

www.koreapart.com

Our main products are HUB AXLE, SWING, TRAVEL REDUCTION, TRANSMISSION, HYDRAULIC PUMP, SEALS and some related parts for heavy equipment since company foundation. Through continuous development and quality improvement, we were able to gain trust from customers and become the top company in Korea.

Thanks for your visiting our site and welcome your enquiries.

www.koreapart.com

Precision Engineering for Heavy-Duty Excavators

This swing reduction unit leverages advanced planetary gear technology and high-strength alloy steel to deliver maximum efficiency and reliability. Designed for both tire and crawler type excavators, its compact form allows easy installation and maintenance, supporting various gear ratios to suit specific operational needs. The integration of heat treatment and anti-corrosion coatings ensures a long lifespan even under demanding conditions.

Superior Sealing and Lubrication System

Equipped with a double lip oil seal and dirt excluder, the swing reduction ensures optimal protection against external contaminants. The integrated sealed oil bath lubrication system maintains smoother gear operation, reducing wear and extending service intervals. This robust sealing setup guarantees dependable performance in tough working environments and extreme temperature variations.

Customizable and Maintenance-friendly Design

Available in standard OEM and custom sizes, the swing reduction can be tailored to meet specific machinery requirements. Its flange-mounted configuration simplifies installation, while the shock-resistant cylindrical housing improves durability. The maintenance-friendly design, along with a noise level under 80 dB, makes it an ideal choice for modern construction sites.

FAQ's of TIRE(Wheel) and Crawler type EXCAVATOR Swing reduction:

Q: How does the swing reduction unit enhance excavator performance?

A: The swing reduction unit delivers high output torque (10,000-70,000 Nm) with a compact planetary gear design, translating hydraulic power into precise, controlled excavator rotation. This boosts operational efficiency, enabling robust swing motions in both tire and crawler type excavators for demanding construction applications.Q: What is the process for mounting the swing reduction to an excavator?

A: Installation is straightforward, as the unit is flange-mounted. It is compatible with most major excavator brands and comes in various sizes to match OEM specifications or custom setups. All necessary mounting points and clearances are designed into the housing for hassle-free integration.Q: When should operators perform swing reduction maintenance?

A: Maintenance intervals are typically extended due to the sealed oil bath lubrication system and precision gear machining. Operators should inspect the system during scheduled machinery servicing, especially if exposed to extreme conditions, but frequent maintenance is minimized by the robust sealing and construction.Q: Where are these swing reduction units manufactured and supplied from?

A: These units are manufactured, exported, and distributed from South Korea, ensuring global compatibility and supply reliability. The manufacturer offers packing in moisture-protected wooden crates or pallets for secure transportation.Q: What benefits does the double lip oil seal provide in this swing reduction?

A: The double lip oil seal, paired with a dirt excluder, maximizes resistance to dust and water ingress, adhering to IP65 protection standards. This prolongs gear life, reduces the risk of oil loss or contamination, and maintains efficient operation in harsh working environments.Q: How does the swing reduction unit accommodate different excavator models and sizes?

A: The unit's modular design allows for a wide range of gear ratios (18:1 to 150:1), torque outputs, and diameters (230-690 mm). Custom sizing and finishes ensure compatibility with varied OEM requirements, providing tailored solutions for diverse excavator configurations.Q: What makes the swing reduction maintenance-friendly?

A: The integrated sealed oil bath lubrication reduces wear and extends service intervals, while the flange-mount setup and shock-resistant design facilitate quick access for inspection and servicing, minimizing downtime and simplifying routine maintenance procedures.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese