Smart MCT G-AiD (4 Axis)

Product Details:

- Size Standard industrial

- Lubricating System Automatic centralized lubrication

- Usage & Applications Automated metal cutting, aerospace, automotive, manufacturing industries

- Capacity 500 units/day

- Shape Rectangular base

- Motor Power 2.2 kW Servo Motor

- Surface Finish Polished

- Click to View more

Smart MCT G-AiD (4 Axis) Price And Quantity

- 1 Unit

Smart MCT G-AiD (4 Axis) Product Specifications

- AI-driven CNC multi-axis machining

- 380V AC

- High-grade alloy steel

- Standard industrial

- Precision coating

- Automatic centralized lubrication

- Automated metal cutting, aerospace, automotive, manufacturing industries

- 2.2 kW

- 500 units/day

- Rectangular base

- 2.2 kW Servo Motor

- 1200 mm x 800 mm x 1750 mm

- 6 bar

- Polished

- Grey & Blue

- Max workpiece diameter 300 mm

- Servo drive

- Less than 65 dB

- Smart MCT G-AiD (4 Axis)

- AI error correction, real-time monitoring, touch panel control, energy saving

- Electric

- 950 kg

Product Description

Product Description

Product Specification

- Spindle : Max 30,000RPM 3.6kW

- ATC : Tool detect sensor 7ea, 6

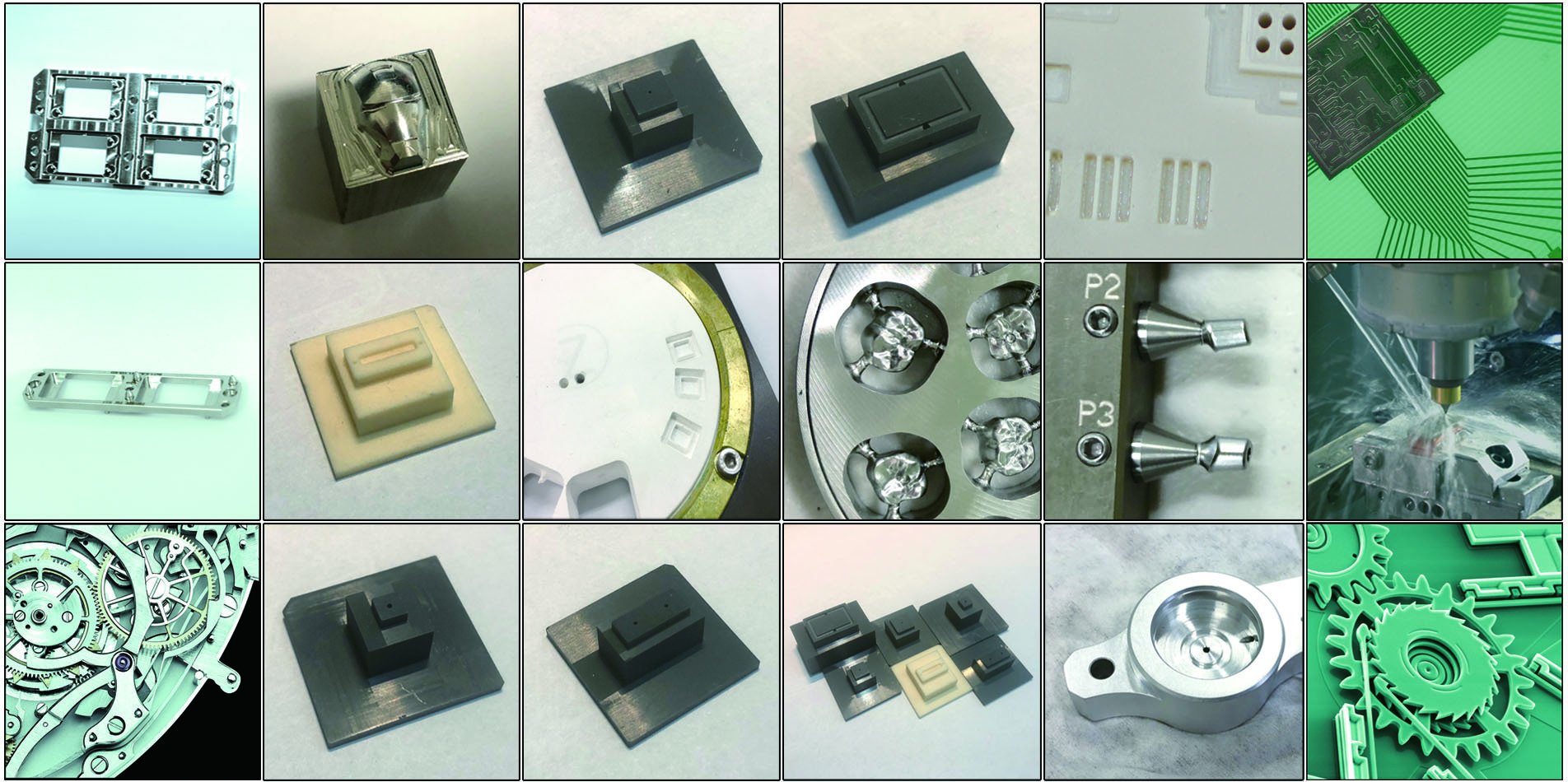

- Material : Titanium, Industrial Ceramic, Aluminum, Sus, Steel, SiC, Carbon, ALN, Etc.

- Motor : AC servo with IP67 absolute system

- Working Area : 100*100 mm

- Power Requirement : CE, KCs

- Weight : 336kg

- External Dimensions : 600*780*1800 mm

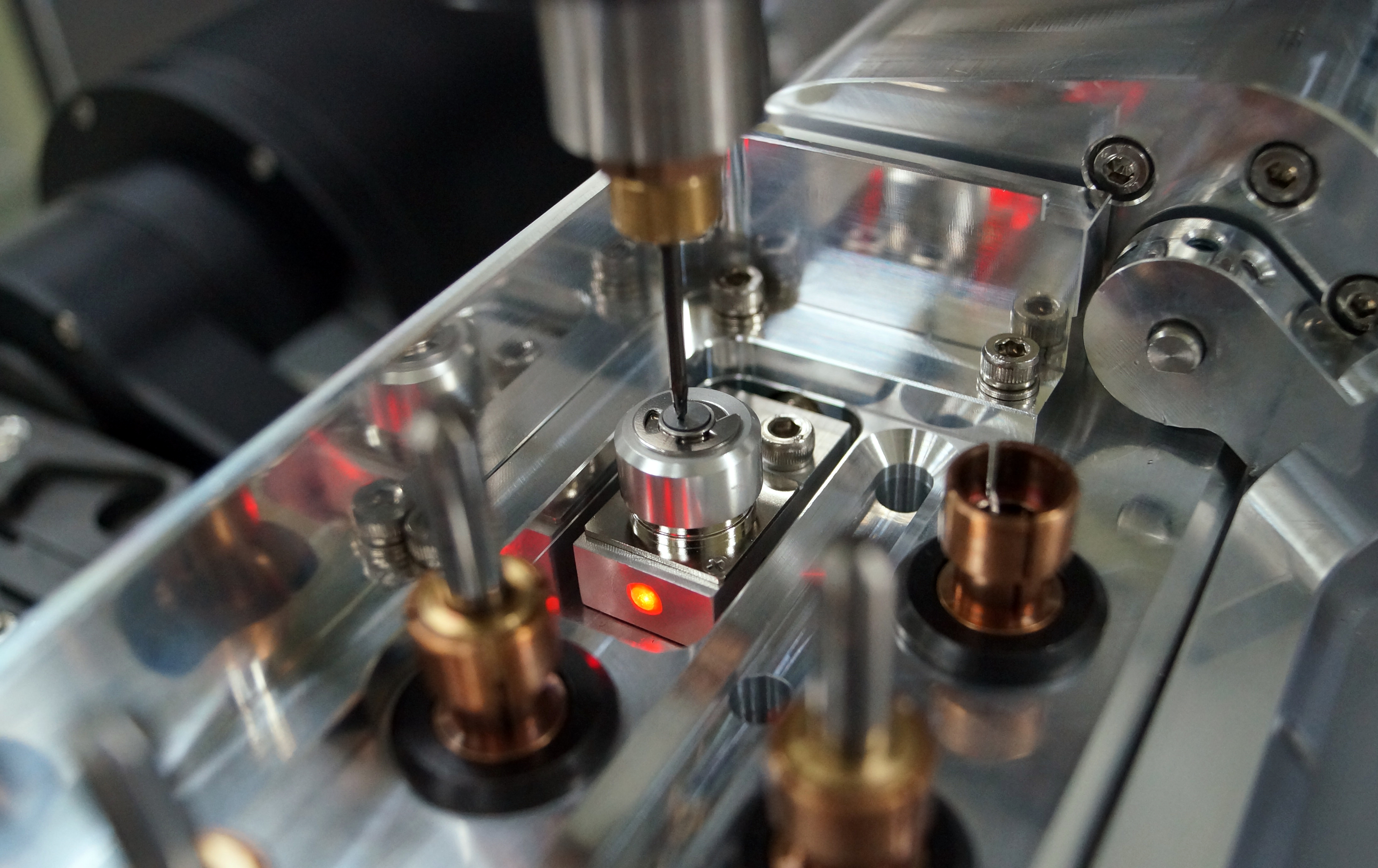

Feature 1 is Multiple Jig Solution

Vice and various jigs can be mounted on the master jig, according to the material. And also, 4-axis and 5-axis enables G-AiD 360 degrees processing with one time setting of materials. MiRHO provide optimal milling solutions for customer s application.

Features 2 is Optimized Motion Controller

G-AiD operating system is designed for users of the FANUC system adapt G-AiD s easily. Deltatu controller of precise motion control, realized the post optimized processing system. MIRHO s unique Compensation Table System minimizes even the tolerance of jigs.

Features 3 is Easier User Interface

G-AiD user interface is simply designed and easy to use. Intuitive icons like smartphone apps will let you operate machines even with simple training. Once the basic setting is completed, user can operate touching only three buttons.

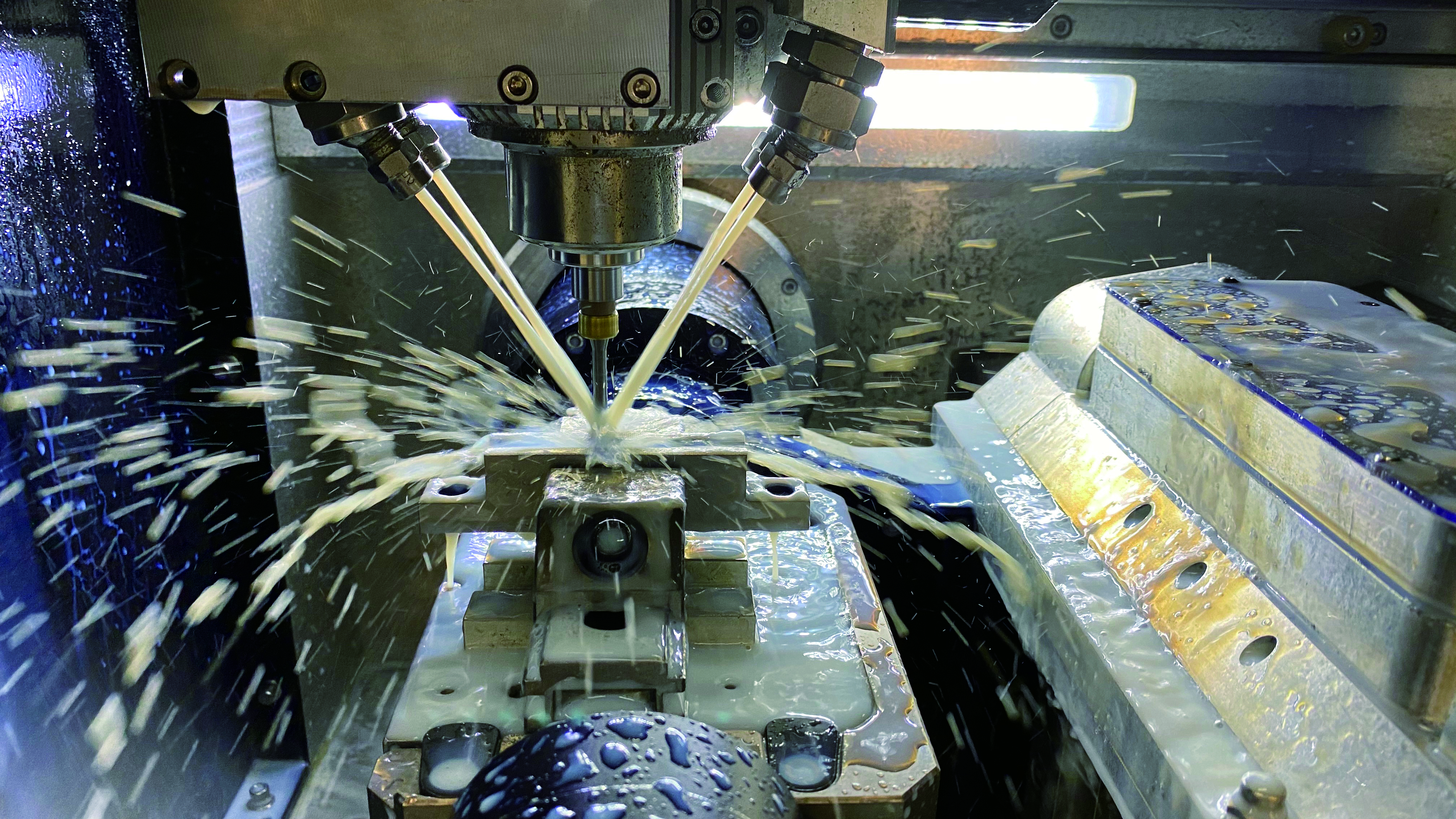

Features 4 is High Speed Milling

G-AiD spindle (maximum 3.6kW and 30,000RPM) is installed in G-AiD. Our test results of G-AiD s shows about 2-2.5 times faster processing than general MCT was possible. Average of general MCT ,000-12,000 RPM, G-AiD 30,000 RPM.

Features 5 is Automatic Tool Length Measurement

G-AiD is equipped with a tool sensor to measure the tool length for every tool change. Accurate tool length compensation for the Z-axis is possible. Checking tool breakage or excessive wear is available by prompt alarm sign when it occurs.

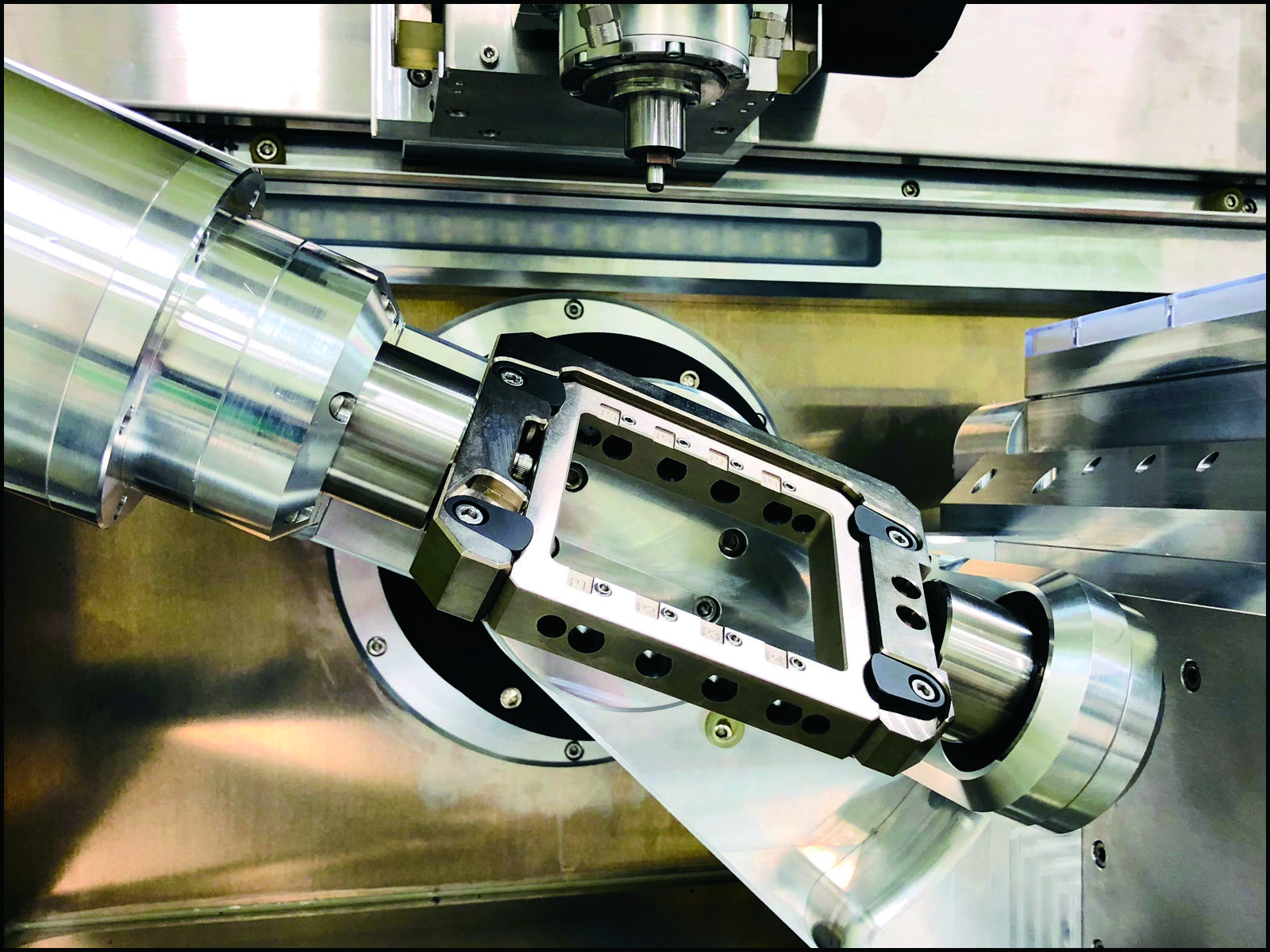

Features 6 is Optimized Footprint and Low-Cost High Efficiency

G-AiD is perfectly optimized to small & precise applications. It needs only 1/6 space of normal MCT and costs only half price. If you choose G-AiD, you can get more productivity with current budget and space. (Average of general MCT 2,000mm-3,000mm(W). G-AiD 600mm x 780mm x 18,000mm (W x H x D).)

Our Company

www.mirho.co.kr.

Precision and Efficiency Redefined

Harnessing advanced AI-driven control, Smart MCT G-AiD achieves repeatability within 0.005 mm and delivers up to 6000 rpm spindle speeds. The automatic tool changer and programmable coolant system optimize tool life and part quality, ensuring your workflow remains uninterrupted and productive. Designed for floor mounting, it fits seamlessly into most industrial settings, offering high daily capacities for demanding production schedules.

Comprehensive Connectivity and Control

The integrated Ethernet and USB interfaces streamline connectivity, allowing for rapid program transfers and system updates. The responsive touch panel and real-time monitoring support instant adjustments and efficient troubleshooting, while the AI error correction reduces waste and boosts output consistency. Data logging capabilities offer managers detailed production and performance analytics for continuous process improvement.

Built for Demanding Environments

Crafted from high-grade alloy steel with precision coatings, the Smart MCT G-AiD withstands the rigors of industrial use. The automatic centralized lubrication and programmable coolant systems ensure reliable operation in diverse conditions, while the machine operates safely at noise levels below 65 dB. Designed with user safety in mind, features include emergency stop and auto fault detection for peace of mind during operations.

FAQs of Smart MCT G-AiD (4 Axis):

Q: How does the Smart MCT G-AiD enhance production efficiency in metalworking applications?

A: This machine features an automatic tool changer, AI-driven control for real-time adjustments, and programmable coolant and lubrication systems. These allow for minimized manual intervention, reduced downtime, and optimized machining processes, significantly elevating overall production throughput and part accuracy.Q: What industries most commonly use the Smart MCT G-AiD and for what applications?

A: The Smart MCT G-AiD is widely used in aerospace, automotive, and general manufacturing for automated metal cutting. It is designed for complex, precision-oriented production environments requiring rapid, consistent output while maintaining tight tolerances.Q: When is on-site installation support available, and what does it include?

A: On-site installation and training are provided upon machine delivery, coordinated with the customers schedule. The support covers machine setup, system integration, user operation training, and safety protocol instructions to ensure seamless production launch.Q: Where should the Smart MCT G-AiD be installed for optimal performance?

A: It is designed for floor-mounted installation in industrial environments, operating best in spaces with a consistent temperature range (10C to 40C), proper ventilation, a stable power supply (380V AC), and accessibility for routine maintenance.Q: What is the process for connecting and operating the Smart MCT G-AiD with CAD/CAM software?

A: The machine supports major CAD/CAM software via Ethernet or USB. Users can load machining programs directly through these interfaces, utilize the touch panel for setup, and the AI controls for real-time program execution and error correction.Q: How does the safety system function on the Smart MCT G-AiD?

A: Integrated safety features include an emergency stop for immediate shutdown, auto fault detection for real-time monitoring, and energy-saving functionalities. These safeguards help prevent accidents and minimize downtime during operation.Q: What benefits does the AI-driven control offer over traditional systems?

A: The advanced G-AiD AI system enables error correction, predictive maintenance, and adaptive machining processes. This results in reduced waste, improved part quality, and higher operational efficiency, especially during high-speed, complex cutting tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese