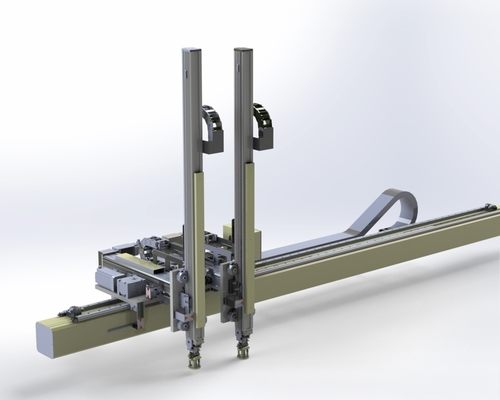

Gantry Robot System

Product Details:

- Shape Rectangular (Rail Track Linear)

- Diameter N/A (Uses linear rails, not rotary axes)

- Usage & Applications Material Handling, Palletizing, Loading & Unloading, Assembly Automation, Pick and Place

- Noise Level <70 dB

- Drive Type Servo Motor/Ball Screw & Linear Guideways

- Features High Repeatability, Programmable, Modular Design, Multi-Axis Movement

- Size Custom as per application

- Click to View more

X

Gantry Robot System Price And Quantity

- 1 Set

Gantry Robot System Product Specifications

- Payload: 50 kg 250 kg

- 220V/380V AC, 50/60Hz

- Powder coated/Painted

- Servo Motor: 0.75 kW6 kW

- Customizable Typical range: 5m10m (L) x 2m4m (W) x 1.8m4m (H)

- Electric

- Automatic/Centralized

- 1200 kg 3200 kg

- Matt/Gloss

- Stainless Steel, Aluminium Alloy

- Industrial Grey/Blue/White

- Gantry Robot System

- <70 dB

- High Repeatability, Programmable, Modular Design, Multi-Axis Movement

- Custom as per application

- N/A (Uses linear rails, not rotary axes)

- Material Handling, Palletizing, Loading & Unloading, Assembly Automation, Pick and Place

- Automated/CNC Control

- Rectangular (Rail Track Linear)

- Servo Motor/Ball Screw & Linear Guideways

- 0.60.8 MPa (If pneumatic assist used)

- 2.2 kW to 10 kW (Varies by model)

Product Description

Products Description

Gantry Robot System of DMT have been recognized for its technology through various independent development patents, and it can be applied to high-speed, high-precision, and high-load work has been showing many performances. - High Speed, High Accuracy, Long life time - Various Gantry Robot System Model by standardization.

Product Specification

- Applying V type guide type _strong durability, moment power up

- Applying U Type guide type for strong pitting resistance

- Position accuracy improved: pre pressure adjustment by eccentric bushing

- Helical Type Rack & pinion _ Low noise4, High Accuracy, Long life time

- High response. High speed/precision:3m/sec repetitive accuracy: 0.1mm

Versatile Multi-Axis Automation

With 2, 3, or 4 axis options and compatibility with multiple communication standards, this Gantry Robot System supports diverse industrial applications. Its programmable controllers, flexible mounting, and customizable end effectors make it ideal for material transfer, assembly automation, and specialized pick-and-place tasks, adapting seamlessly to varied operational requirements.

Exceptional Precision and Performance

Engineered for high-precision tasks, this system ensures accurate and repeatable motion, maintaining 0.05 mm to 0.1 mm positioning accuracy and 0.03 mm repeatability. Designed for rapid traversing speeds up to 3 m/s across custom travel lengths, it balances reliability with productivity, ensuring consistent output in demanding industrial environments.

Smart Integration and Safety

The Gantry Robot System offers easy integration with MES and other industrial automation software, thanks to its advanced control interfaces (Ethernet/IP, ProfiNet, RS485). Safety is optimized with emergency stops, overload protection, and full enclosures, supporting safe operation in factories and warehouses while minimizing downtime and risk.

FAQ's of Gantry Robot System:

Q: How does the Gantry Robot System improve operational efficiency in factories and warehouses?

A: The system automates key processes like material handling, palletizing, and pick-and-place tasks, significantly reducing manual labor. With its high speed (up to 3 m/s), precise motion (0.05 mm - 0.1 mm), and multi-axis movement, productivity is increased while operational errors and downtime are minimized.Q: What end effectors are compatible with the Gantry Robot System?

A: This robot system supports a broad selection of end effectors, including grippers, magnetic tools, suction pads, and custom-designed tooling. This adaptability allows it to handle different materials and perform specialized tasks to suit specific industrial applications.Q: When should maintenance be performed on the Gantry Robot System?

A: Regular inspection is recommended according to the operational schedule, but the system's low-maintenance, modular design combined with its automatic or centralized lubrication system typically reduces required maintenance intervals. Modular replacement further simplifies servicing, minimizing downtime.Q: Where can the Gantry Robot System be installed within an industrial facility?

A: The system offers flexible mounting options-floor, ground, or overhead-which enables seamless integration in a variety of industrial settings such as warehouses and production lines. Its modular construction allows installation over travel lengths up to 15 meters, supporting custom layouts.Q: What is the installation process and how long does it take?

A: Installation generally takes between 2 to 3 days, depending on configuration and site preparedness. The process involves anchoring the modular frame, connecting the controller, integrating safety features, and commissioning the system, following which it is ready for operational tasks.Q: How does the system ensure safety and regulatory compliance during operation?

A: Multiple safety features are integrated, such as emergency stop switches, overload protection, and safety enclosures. These, combined with reliable electrical components and standardized interfaces, support compliance with industrial safety norms and reduce operator risk.Q: What are the main benefits of integrating this Gantry Robot System with MES or automation software?

A: Seamless integration enhances real-time monitoring, process control, and data-driven optimization. This connectivity streamlines workflow management, supports predictive maintenance, and ensures consistent high-quality output throughout the system's service life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese