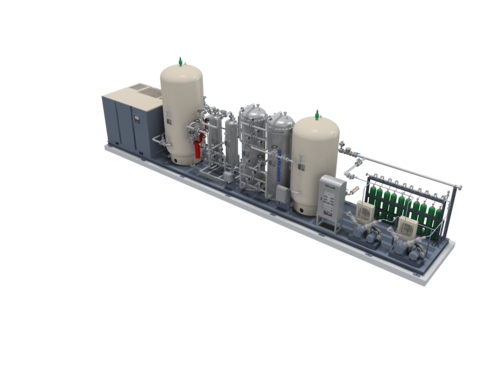

O2 (V)PSA Package

Product Details:

- Lubricating System Oil Lubricated

- Usage & Applications Oxygen Generation for Industrial & Medical use

- Motor Power 3.75 kW

- Drive Type Electric Motor Driven

- Surface Finish Smooth

- Shape Rectangular Unit

- Noise Level Low

- Click to View more

X

O2 (V)PSA Package Price And Quantity

- 1 Unit

O2 (V)PSA Package Product Specifications

- Blue & Grey

- Oil Lubricated

- 3.75 kW

- Standard

- O2 (V)PSA Package

- Electric

- 5 Nm/hr Oxygen Output

- 1800 mm x 1100 mm x 1750 mm

- Low

- Rectangular Unit

- 4.5 kg/cm

- approx. 700 kg

- Mild Steel

- Electric Motor Driven

- Vacuum Pressure Swing Adsorption (VPSA)

- Smooth

- Powder Coated

- Oxygen Generation for Industrial & Medical use

- Fully Automatic, Skid Mounted, High Purity Oxygen Output, Energy Efficient

- 3.75 kW

- 380V / 50Hz

Product Description

O2 (V)PSA Package

O2 PSA Generator utilizes ZMS(Zeolite Molecular Sieve) to separate the oxygen gas from air. The Principle is to make use of different adsorption force of gases in air at pressure equalizing. The whole process of O2 PSA generator consists of Pressurization, Production, Purge, Equilibrium of pressure and Desorption. Atmospheric air consists of 21% oxygen, 78% nitrogen and 0.9% argon. Anyoxy, which is specialized by ASPE and exported to the global market, uses VPSA (Vacuum Pressure Swing Adsorption) to separate oxygen, and ZMS (Zeolite Molecular Sieve) is used to separate oxygen. This adsorbent is a product that the system is perfectly designed and produced so that it can be used semi-permanently.

Air Compressor

Air compressor is the equipment to produce compressed air.

Compressed air is used for separating oxygen from air.

In the process of compression, moisture and heat happen.

To remove them, built-in or independent air dryer and after-cooler are necessary.

Filter

Filter is used for removing dust, particle and oil in the compressed air.

Desiccant air dryer

This is used for removing moisture by using adsorbent.

It consists of two adsorbers and it has the repeated cycles of adsorption and regeneration

PSA Generator

In order to separate the oxygen from the compressed air, ZMS(Zeolite Molecular Sieve) is used as adsorbent.

O2 PSA system consist of pressurization, production, purge, equilibrium of pressure and regeneration.

Oxygen storage Tank

It is a buffer (storage) tank to supply the processed oxygen with certain pressure, purity and flow.

LCP

LCP has control of the whole system into operation automatically or manually.

It also indicates purity, pressure and flow of the produced oxygen.

Oxygen supply

The purity of the produced oxygen is 90 - 95%. Flow and pressure depend on customer's needs.

High pressure Compressor

It is a high pressure compressor to fill oxygen cylinders at 125-150BarG.

Manifold and Oxygen cylinder

Pipelines are designed to fill oxygen cylinders at the same time and cylinders are connected at the end of manifold.

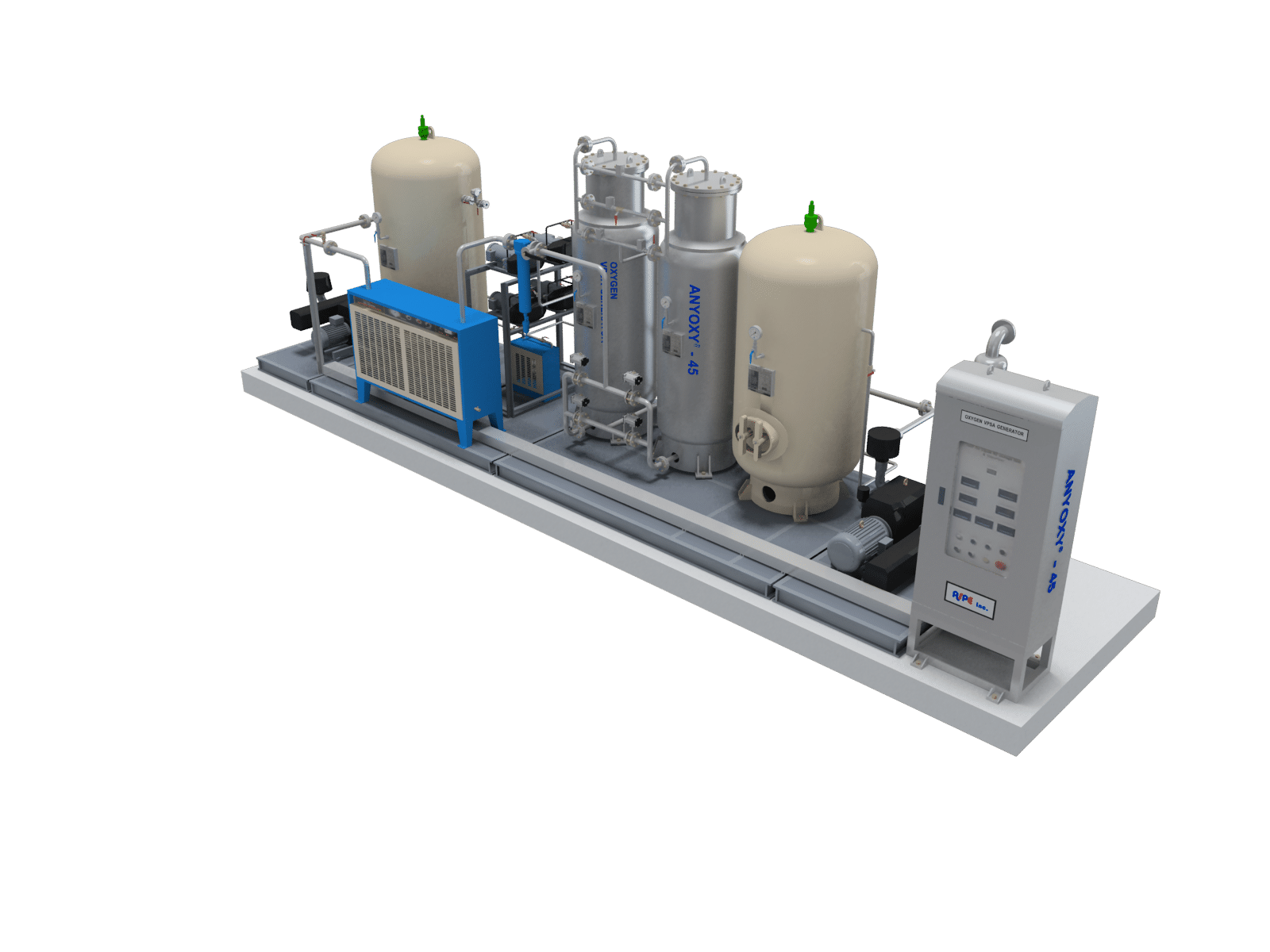

[O2 VPSA Generator]

Blower

Blower is the equipment to produce supplied air.

Supplied air is used for separating oxygen from air.

After-cooler

The purpose of after cooler is to reduce temperature of supplied air down to ambient temperature.

VPSA Generator

In order to separate the oxygen from the blowing air, ZMS(Zeolite Molecular Sieve) is used as adsorbent.

VPSA consists of 2 adsorbers. While adsorber "A" is under the process of Pressurization, Production, Purge, Equilibrium of pressure and Desorption, adsorber "B" is regenerated to produce oxygen.

Vacuum pump

The purpose of vacuum pump is for removing the adsorbed gases such as nitrogen from the adsorbent.

Oxygen buffer Tank

It plays a part as a buffer in sending the produced oxygen of low pressure into the oxygen compressor stably.

Oxygen compressor

It is used for compressing oxygen to the extent of what a user need.

After-cooler

The purpose of After cooler is to reduce the temperature of compressed oxygen heated in the process of pressurization.

Oxygen storage tank

It is a buffer (storage) tank to supply the compressed oxygen with certain pressure, purity and flow.

LCP

LCP had control of the whole system into operation automatically or manually.

It also indicates purity, pressure and flow of the produced.

Oxygen supply

The purity of the produced oxygen is 90-95%. Flow and pressure depend on customer`s needs.

Advanced VPSA Technology

Utilizing Vacuum Pressure Swing Adsorption (VPSA), this package consistently produces oxygen at 93% 3% purity, making it suitable for critical industries and healthcare environments. The twin-bed system maximizes operational efficiency, while fully automatic and manual controls enable flexible, user-friendly operation.

Robust Design & Reliable Performance

Crafted from powder-coated mild steel, the skid-mounted unit provides durability and easy installation. The low-noise electric motor-driven system ensures a pleasant working environment. Adjustable oxygen flow and high outlet pressure meet diverse needs, supported by reliable after-sales service.

Versatile & Energy Efficient Solution

With a capacity of 5 Nm3/hr and ambient operating range from 5C to 45C, the package is ideal for multiple oxygen applications in industrial and medical settings. The system is designed for minimal energy consumption, helping reduce operational costs without compromising performance.

FAQ's of O2 (V)PSA Package:

Q: How is oxygen purity maintained in the O2 (V)PSA Package?

A: Oxygen purity is maintained at 93% 3% through the advanced Vacuum Pressure Swing Adsorption process and a twin-bed system, which continuously removes impurities using oil-free, dry compressed air as input.Q: What industries can benefit from using this O2 (V)PSA Package?

A: This system serves both medical and industrial sectors, including hospitals, laboratories, manufacturing plants, and other facilities requiring a steady supply of high-purity oxygen.Q: Where can the O2 (V)PSA Package be installed?

A: The skid-mounted design allows easy installation in various locations, including factory floors, medical centers, and remote industrial sites as long as ambient temperatures are between 5C and 45C.Q: What process does the VPSA technology use to generate oxygen?

A: Vacuum Pressure Swing Adsorption uses dual beds filled with adsorbent material to separate oxygen from ambient air. The process cycles automatically to produce pure oxygen and vent out other gases.Q: How can users adjust the oxygen flow rate?

A: The package features a flow rate adjustment mechanism accessible via the PLC-controlled panel, allowing precise control to match specific application needs.Q: When is after-sales support available for this package?

A: Comprehensive after-sales support is available to assist with installation, operation, and maintenance during and after the warranty period.Q: What are the main benefits of choosing this oxygen generation system?

A: Key benefits include fully automatic operation, high energy efficiency, low noise levels, robust construction, customizable output, and support from distributor, exporter, manufacturer, and supplier networks in Korea South.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese