AL-PRO END MILLS

Product Details:

- Surface Finish High Precision/Polished

- Lubricating System External Coolant Recommended

- Diameter 2mm to 20mm (custom sizes available)

- Size Available from 2mm up to 20mm diameter

- Drive Type Straight Shank, Suitable for CNC and Manual Machines

- Usage & Applications Aluminum machining, Non-ferrous metal cutting, High-speed milling operations

- Noise Level Depends on machine setup

- Click to View more

AL-PRO END MILLS Product Specifications

- CNC Ground, Advanced Flute Design

- Cylindrical Shank, End Cutting

- Ultra-sharp cutting edge, High chip evacuation, Anti-vibration design, Long tool life

- Optimized for high-feed and high-speed machining

- Manual

- Polished/Uncoated

- Depends on machine setup

- Aluminum machining, Non-ferrous metal cutting, High-speed milling operations

- Depends on diameter & length

- 2mm to 20mm (custom sizes available)

- End Mill

- Available from 2mm up to 20mm diameter

- Straight Shank, Suitable for CNC and Manual Machines

- External Coolant Recommended

- Metallic Grey/Silver

- Carbide (Special grade for Aluminum machining)

- High Precision/Polished

- Varies by size; standard lengths available

Product Description

Product Description

1 Flutes Square(Flat) End mills for Aluminium, Resin, ABS

- Outstanding performance for ABS, Acryl, Aluminium, Non-Ferrous Metal

- Suitable for Cut-off and Side Cutting due to well chip flow

- Available to choose the variety of cutting length and overall length

Company Information

We have been striving for professional manufacturer of MILLING BUR which keeps the same quality from a batch to another batches. Lean process makes it possible to be a competitive in cost and lead time. Intensive development was resulted in broad range tools to fit in many different machine types. We believe that these achievements contribute customers to reach their objective.

The competence of HANSONG M&T is developing and manufacturing END MILL and MILLING BUR. The company will continue the focus on these core technologies to keep the position of professional manufacturer.

Optimized for Aluminum and Non-Ferrous Materials

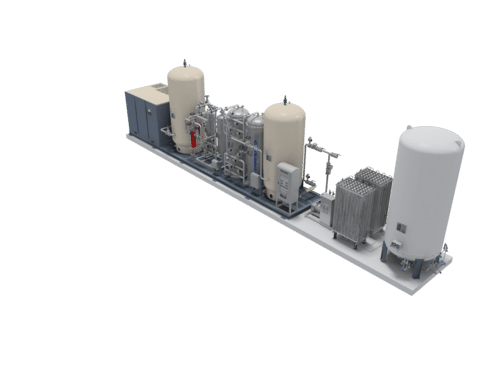

AL-PRO End Mills are specially designed for machining aluminum, copper, brass, plastics, and other non-ferrous alloys. Their high helix angle and advanced flute geometry enable efficient chip evacuation, preventing build-up and maintaining surface integrity. This ensures users achieve excellent machining results even during high-speed operations.

Advanced Flute Design and Ultra-sharp Cutting Edge

With options for 2, 3, or 4 flute types, AL-PRO End Mills support a variety of cutting requirements and feed rates. The tools are CNC ground from micro grain carbide, delivering high hardness and precision. The anti-vibration design reduces noise and tool wear, granting longer tool life and higher accuracy in demanding milling tasks.

Flexible Options and Universal Compatibility

Customers can select from different cutting lengths (short, medium, long) and tip types (centre cutting) to match their specific application. Available in diameters from 2mm up to 20mm, these end mills fit most CNC and VMC machines with straight shank drive, offering universal solutions for both manual and automated machining environments.

FAQ's of AL-PRO END MILLS:

Q: How do AL-PRO End Mills improve chip removal in aluminum machining?

A: AL-PRO End Mills utilize a high helix angle and advanced flute design, allowing for superior chip evacuation. This reduces heat generation and prevents clogging during high-speed milling, leading to smoother finishes and improved machining efficiency.Q: What applications are best suited for AL-PRO End Mills?

A: These end mills are optimized for cutting aluminum, copper, brass, plastics, and non-ferrous alloys. They are ideal for high-speed machining, precision milling, manufacturing of automotive and aerospace components, and general metalworking tasks.Q: When should I choose 2, 3, or 4 flute end mills for my operation?

A: The selection depends on your machining requirements. 2-flute end mills are best for softer materials and higher chip clearance, 3-flute for balanced chip evacuation and finish, and 4-flute for superior surface finish and rigidity in tougher materials.Q: Where can I use AL-PRO End Mills?

A: AL-PRO End Mills are compatible with most CNC and VMC machines due to their universal straight shank. They can also be used in manual milling setups, making them suitable for a range of industry and workshop environments.Q: What is the process for maintaining and storing AL-PRO End Mills?

A: To extend tool life, use external coolant during machining and store each end mill in its individual plastic case or blister pack to prevent damage. Regular inspection and proper cleaning after use also enhance tool longevity and performance.Q: How does the protective nano coating benefit the end mill?

A: The nano coating option provides increased wear resistance, lower friction, and better heat dissipation, which results in longer tool life, improved cutting performance, and reduced risk of material adhesion during aluminum machining.Q: What sizes and cutting lengths are available for AL-PRO End Mills?

A: AL-PRO End Mills are offered in diameters from 2mm up to 20mm, with short, medium, and long series cutting lengths. Custom sizes are also available upon request to accommodate specialized manufacturing needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese