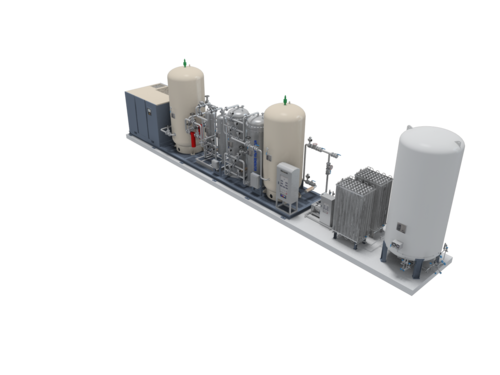

N2 PSA - Membrane Package

Product Details:

- Capacity 1 Nm/hr to 300 Nm/hr

- Drive Type Electric Driven

- Usage & Applications Industrial Nitrogen Generation, Food & Beverage Packaging, Chemical Processing, Electronics Manufacturing

- Lubricating System Oil-Free / Oil-Lubricated as per requirement

- Motor Power As per Unit Configuration

- Features High Purity, Energy Efficient, Easy Installation, Low Maintenance

- Size Compact / Skid Mounted Unit

- Click to View more

N2 PSA - Membrane Package Price And Quantity

- 1 Unit

N2 PSA - Membrane Package Product Specifications

- 220V/380V/415V, 50/60 Hz

- 1 Nm/hr to 300 Nm/hr

- 5-12 Bar (kg/cm)

- 250-800 kg (varying by capacity)

- Powder Coated / Painted / Matt Finish

- PSA (Pressure Swing Adsorption) / Membrane

- Oil-Free / Oil-Lubricated as per requirement

- N2 PSA - Membrane Package

- Rectangular Skid Base

- Membrane Diameter: 4 - 8 (for membrane models)

- Industrial Nitrogen Generation, Food & Beverage Packaging, Chemical Processing, Electronics Manufacturing

- Compact / Skid Mounted Unit

- Electric Driven

- Electric

- As per Unit Configuration

- Below 75 dB

- 3 kW to 15 kW (depending on model)

- Smooth / Corrosion Resistant

- Custom / As per requirement (e.g., 1200 x 1000 x 1500 mm)

- High Purity, Energy Efficient, Easy Installation, Low Maintenance

- Mild Steel / Stainless Steel

- White / Blue / Customized

Product Description

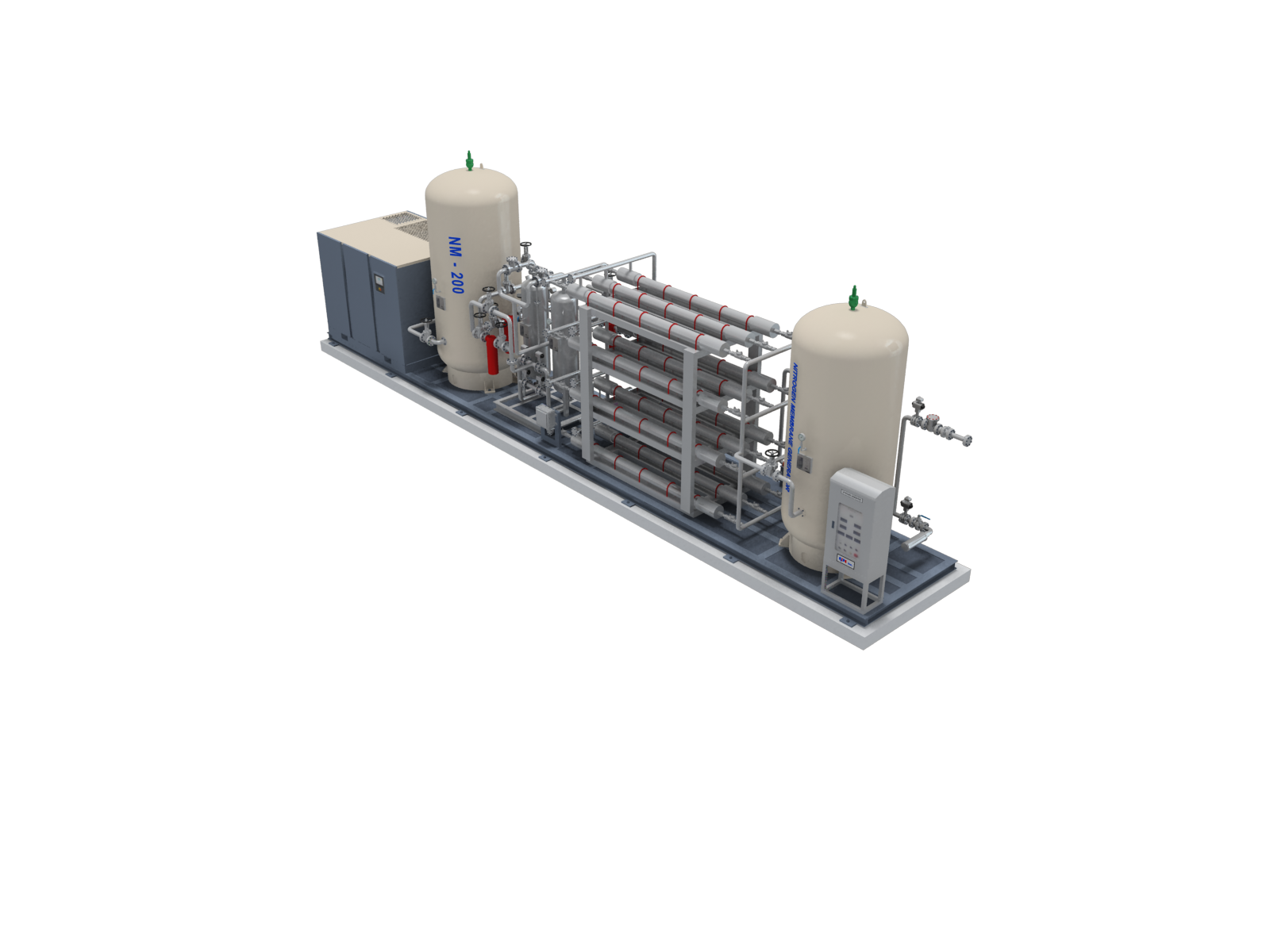

N2 PSA & Membrane Package

N2 PSA Package N2 PSA Generator utilizes the properties of CMS(Carbon Molecular Sieve) to separate nitrogen in air. CMS has the adsorption pore which adsorbs oxygen faster & more than nitrogen from the air. The whole process of nitrogen generator consists of Pressurization, Production, Equilibrium of pressure, Cleaning and Purge.

RIPE Inc.

N2 Membrane Package The Oxygen gas with the high permeability speed permeates out first through vent port. Nitrogen gas with the low permeability speed comes out later through the end of hollow fiber, when the compressed air passes through the membrane. The principle is to make use of the difference of the permeability speed of gas.

Application

Injection molding

Purge

Laser cutting

Fire extinguisher

Packing

Heat treatment

Soldering

Reflow

Photo Lab and Electronics

Product Application

Air Compressor

Air compressor is the equipment to produce compressed air.

Compressed air is used for separating nitrogen from air.

In the process of compression, moisture and heat happen.

To remove them, built-in or independent air dryer and after-cooler are necessary.

Filter

Filter is used for removing dust, particle and oil, etc. in compressed air.

Desiccant air dryer

This is used for removing moisture by using adsorbent.

It consists of two adsorbers and it has the repeated cycles of adsorption and regeneration.

PSA Generator

In order to separate nitrogen from the compressed air, CMS(Carbon Molecular Sieve) is used as adsorbent.

PSA system consist of pressurization, production, purge, equilibrium of pressure and regeneration.

Nitrogen storage Tank

It is a buffer (storage) tank to supply the oxygen certain pressure, flow, purity.

LCP

LCP has control of the whole system into operation automatically or manually.

It also indicates purity, pressure and flow of the produced nitrogen.

Nitrogen supply

The purity of the produced nitrogen is up to 99.999%. Flow and pressure depend on customers needs.

LN2 Storage tank

It is the equipment for storing liquid nitrogen.

LN2 Vaporizer

It is the equipment for changing nitrogen from liquid into gas through vaporization.

Gas supply unit

In order to supply vaporized nitrogen with the certain pressure.

LCP

It controls the heater that is used when the vaporized nitrogen of certain temperature is required.

Air Compressor

Air compressor is the equipment to produce compressed air.

Compressed air is used for separating nitrogen from air.

In the process of compression, moisture and heat happen.

To remove them, built-in or independent air dryer and after-cooler are necessary.

Air Receiver Tank

Air receiver tank is the equipment to keep supplying the compressed air of certain pressure to the nitrogen generator stably.

It is also for the purpose of handling the load of compressor properly.

Filter

It is used for removing dust, particle and oil, etc. in compressed air.

Desiccant Air dryer

This is used for removing moisture by using adsorbent.

It consists of two adsorbers and it has the repeated cycles of adsorption and regeneration.

Membrane Generator

Membrane generator is to make use of the difference of the permeability speed of gas in order to separate gas.

Such oxygen and moisture with high permeability speed, permeate out first through vent port and then nitrogen gas with low permeability speed as marketable product comes out later through the end of hollow fiber when the compressed air pass through the membrane.

Nitrogen Storage Tank

It is a buffer (storage) tank to supply the oxygen certain pressure, flow, purity.

LCP(Local Control Panel)

LCP has control of the whole system into operation automatically or manually.

It also indicates purity, pressure and flow of the produced nitrogen.

Nitrogen Supply

The purity of the produced nitrogen is up to 99%. Flow and pressure depend on customer s needs.

Efficient Nitrogen Generation

This advanced nitrogen generation package leverages Pressure Swing Adsorption (PSA) or membrane technology to supply a consistent, high-purity gas stream for demanding industrial processes. The system is tailored to deliver nitrogen purity up to 99.999%, making it suitable for applications requiring stringent gas quality control.

Versatile Configurations & Installation

The package supports customizable dimensions and a range of configurations, including flanged or threaded connections, and both mild steel or stainless steel construction. The compact, skid-mounted design and various cooling options ensure straightforward integration into diverse operational environments and industries.

User-Centric Control & Maintenance

Featuring a digital or PLC-based control panel, the system offers intuitive operation and monitoring. Routine maintenance intervals extend up to 12 months or 8,000 hours, ensuring low ongoing costs and minimal downtime, maximizing reliability for continuous production needs.

FAQ's of N2 PSA - Membrane Package:

Q: How does the N2 PSA - Membrane Package generate high-purity nitrogen?

A: The system employs advanced Pressure Swing Adsorption (PSA) or membrane technology to separate nitrogen from compressed air, consistently delivering nitrogen with purity levels up to 99.999%, depending on the selected configuration.Q: What applications can benefit from using this nitrogen generation system?

A: It is ideal for industrial uses such as food and beverage packaging, chemical processing, electronics manufacturing, and any process requiring a reliable supply of high-purity nitrogen.Q: When is routine maintenance required for this system?

A: Scheduled maintenance should be performed every 12 months or after 8,000 hours of operation, ensuring ongoing performance and extending equipment lifespan.Q: Where can the N2 PSA - Membrane Package be installed?

A: The compact, skid-mounted design allows installation in various locations, including factories, manufacturing plants, and facilities with limited space, as it only requires an electrical connection and a compressed air feed.Q: What is the typical start-up time for the unit?

A: The system offers a rapid start-up, becoming fully operational typically within 20 minutes after power-on-minimizing downtime and enabling quick response to production demands.Q: How does the control panel enhance operational efficiency?

A: The digital or PLC-based control panel allows precise adjustment of operating parameters, easy system monitoring, and efficient troubleshooting, improving overall process control and user experience.Q: What are the major benefits of choosing this nitrogen generation package?

A: Key benefits include high nitrogen purity, energy efficiency, easy installation, low operating noise (below 75 dB), minimal maintenance needs, and robust service support such as onsite commissioning and annual maintenance contracts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese