Ship Automation System

Product Details:

- Size Standard

- Usage & Applications Ship Engine, Navigation & Control Automation

- Drive Type Electric Drive

- Shape Rectangular

- Features Touchscreen Interface, Alarm System, Energy Efficient, Easy Maintenance

- Noise Level Below 60 dB

- Motor Power 1.5 kW

- Click to View more

X

Ship Automation System Price And Quantity

- 1 Unit

Ship Automation System Product Specifications

- Automated Lubrication

- 4-8 bar

- Electric

- Up to 1000 operations/hr

- 1200 x 800 x 600 mm

- Stainless Steel

- 2 kW

- 1.5 kW

- Below 60 dB

- Touchscreen Interface, Alarm System, Energy Efficient, Easy Maintenance

- Rectangular

- Electric Drive

- Smooth Finish

- 220-440 V AC

- 65 kg

- Ship Engine, Navigation & Control Automation

- Automatic Control System

- Standard

- Ship Automation System

- Powder Coated

- Blue & Grey

Product Description

Products Description

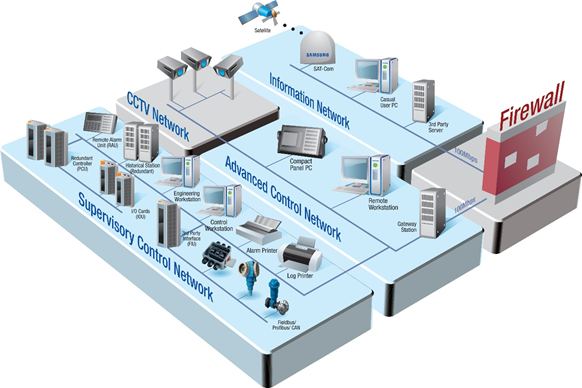

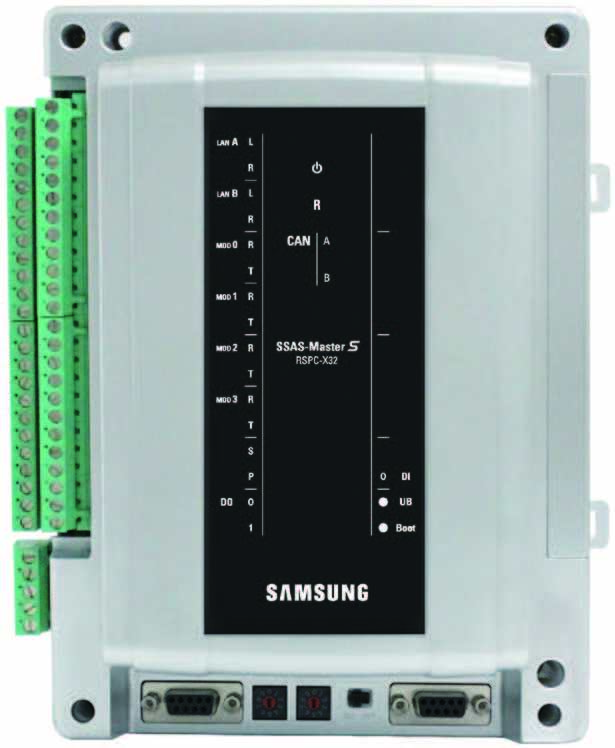

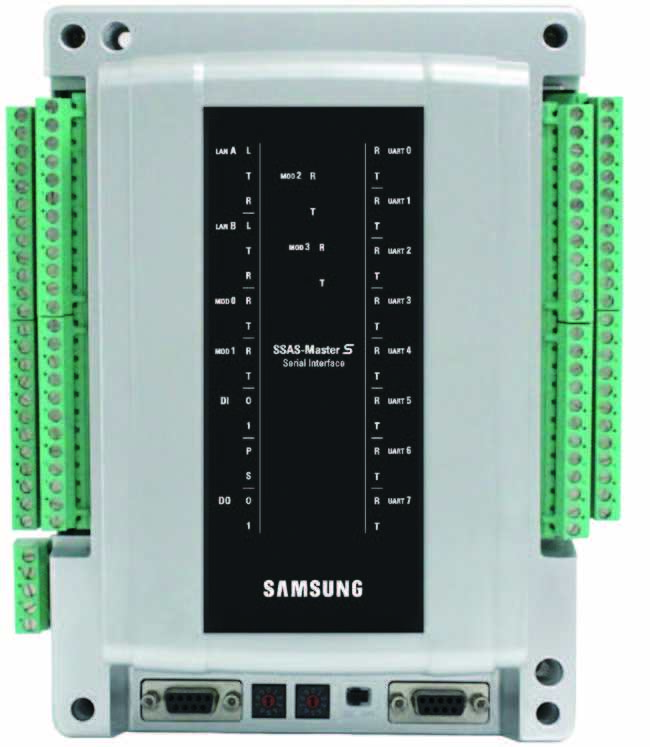

SSAS-Master is Ships Automation System for monitoring and control engine room equipment, cargo equipment. The SSAS-Master hardware(Controllers, I/O cards, EAPs) and Software(Gitos-Master) are developed by our own technology. SSAS-Master is fully redundant system and has reference for almost all kind of vessels such as Bulk Carrier, Tanker, Container, Shuttle tanker and LNG Carrier. Recently the system for FGSS control have been delivered successfully.SSAS-Master is applied for AMS(E/R Alarm Monitoring System), ICMS(Integrated Control &Monitoring System) and IAS(Integrated Automation System).

Specifications-

Product Features-

- High Performance & Reliable Component

- 32bit embedded microprocessor with real time O/S

- Compact and uniformed hardware structure of modules installed on DIN rail

- Surge and short circuit protected I/O cards

- Optimized DBMS provides robustness and scalability on the system configuration and history data.

- Easy extension of applying different equipment with standard interface protocol (Profibus, CANOpen, Device Net, Modbus, NMEA0183, OPC, ODBC,XML,etc.)

- Various reports and simple user defined report generating function.

- Support new technology for customer's needs

- Fault tolerant configuration of process control and database

- Optical isolated fault tolerant control network and I/O network

- Simple replacement of faulty hardware without turning off the system for continuous operation and easy maintenance.

- Fully implementing XML Schema based on IEC61131-6(TC6) PLC Open control language

- Interoperable with other applicable software including internal controls ( Flash Animation, Active-X control, AutoCAD, MS-Word, Adobe PDF, etc.)

- Easy web based monitoring and control user interface with security.

Application : The various vessels such as Tanker, LNGC, Container & Bulk etc.

Seamless Integration and Automation

Utilizing PLC technology and a reliable RS485/Modbus interface, the Ship Automation System delivers advanced control for navigation, engine management, and automated lubrication. The automatic control design enhances precision and reduces manual intervention while supporting real-time data exchange and remote monitoring capabilities. Its compatibility with both sensor and manual inputs allows adaptability for varied maritime operational needs.

Durable Construction, Reliable Performance

Constructed from powder-coated mild steel and stainless steel, the enclosure protects the system against harsh marine conditions, meeting IP54 standards. With its smooth blue and grey finish, the system maintains a professional appearance while withstanding rigorous shipboard use. Its 65 kg structure, 2 kW power capacity, and operation across wide voltage and pressure ranges secure reliable performance under demanding conditions.

User-Friendly Design and Maintenance

The digital LCD display and touchscreen interface make this automation system intuitive to operate. It requires minimal maintenance and offers clear alerts via its alarm system, ensuring quick response to faults. The systems electric drive guarantees operations remain below 60 dB, sustaining a quiet onboard atmosphere. Easy wall-mounting and standardized dimensions facilitate straightforward installation and integration.

FAQs of Ship Automation System:

Q: How does the Ship Automation System enhance ship operation efficiency?

A: The system automates key functions such as engine control, navigation, and lubrication, reducing manual workload and ensuring swift response times. Its programmable logic controller (PLC) optimizes performance, while continuous monitoring and alarms help promptly address any issues, resulting in improved operational efficiency.Q: What is the process for installing the system onboard a vessel?

A: Installation involves wall mounting the enclosure in a suitable location, connecting the power supply (220-440 V AC), and integrating sensors and actuators using manual or automatic inputs. The standardized dimensions (1200 x 800 x 600 mm) and RS485/Modbus interface facilitate straightforward integration into existing ship systems.Q: When should maintenance be performed on this automation system?

A: Routine inspections should be scheduled as per the vessels maintenance cycle or manufacturer recommendations. Thanks to its rugged construction and automated alerts, preventive maintenance is generally limited to periodic checks and cleaning, ensuring minimal system downtime.Q: Where is this automation system most effectively used on ships?

A: It is best suited for engine rooms, navigation control stations, and areas requiring centralized monitoring. Its IP54-rated enclosure and powder-coated finish provide reliable operation even in demanding marine environments prone to humidity and dust.Q: What are the main benefits of using a PLC-controlled ship automation system?

A: PLCs offer highly reliable, programmable control. They enable real-time data processing, ensure swift reactions (<2 seconds), and facilitate easy customization for specific ship requirements, contributing to increased safety, efficiency, and cost savings over the systems lifetime.Q: How is the system monitored and controlled during operation?

A: Operators use the digital LCD and touchscreen interface to monitor system status, set parameters, and respond to alarms. Remote and local access via the RS485/Modbus interface allows both onboard and offsite management, enhancing operational flexibility and responsiveness.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese