W-SCRS Superheated Steam Carbon Regeneration System

Product Details:

- Shape Rectangular Modular Design

- Lubricating System Automatic Centralized Lubrication

- Usage & Applications Regeneration of activated carbon in water treatment, gold mining, and chemical industries

- Capacity Up to 200 kg/h

- Noise Level 75 dB

- Size Standard/Customizable

- Features High efficiency, low energy consumption, continuous operation, easy maintenance, rapid startup

- Click to View more

W-SCRS Superheated Steam Carbon Regeneration System Price And Quantity

- 100 Unit

W-SCRS Superheated Steam Carbon Regeneration System Product Specifications

- Polished

- Electric Motor Driven

- Up to 200 kg/h

- 75 dB

- Anti-corrosive Coating

- 2300 kg

- High efficiency, low energy consumption, continuous operation, easy maintenance, rapid startup

- 30 kW

- Superheated Steam Carbon Regeneration System

- Electric

- 380 V

- Regeneration of activated carbon in water treatment, gold mining, and chemical industries

- 5.5 kW

- 4200 x 1800 x 2100 mm

- Automatic Centralized Lubrication

- Gray

- Standard/Customizable

- 0.8 - 1.2 MPa

- Superheated Steam Regeneration

- Stainless Steel

- Rectangular Modular Design

W-SCRS Superheated Steam Carbon Regeneration System Trade Information

- South Korea

- Telegraphic Transfer (T/T)

- Export Standard Packing

Product Description

Product Description

W-SCRS is activated carbon regeneration system using superheated steam. This system has higher recovery rate and low O&M cost than other A/C regeneration system.

Product Features

No risk of fire by oxygen free low temperature pyrolysis

Compact facility easy O&M and economical

Minimum replacement in A/C properties by superheated steam regeneration - maintain high recovery rate and regeneration yield

High recovery rate due to activation by superheated steam

Possible to install facility without extension of existing site

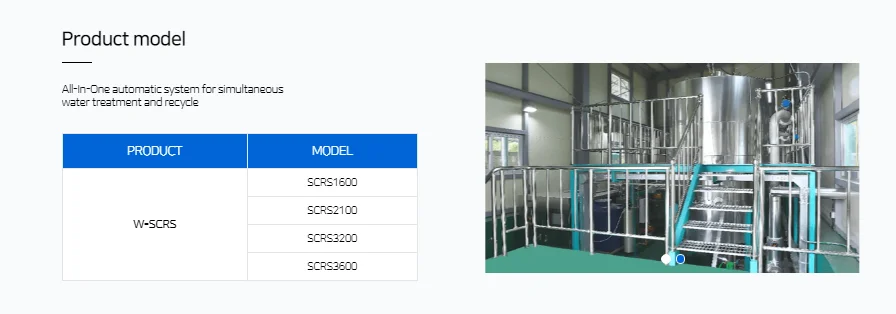

Model and Product

Product Name : W-SCRS

Model : SCRS 1600, SCRS 2100, SCRS 3200, SCRS 3600

Propose for product

Activation Carbon Regeneration

Field of use

Any field where use Activated Carbon for example water treatment plant, industrial water treatment plant, waste and sewage treatment system etc.

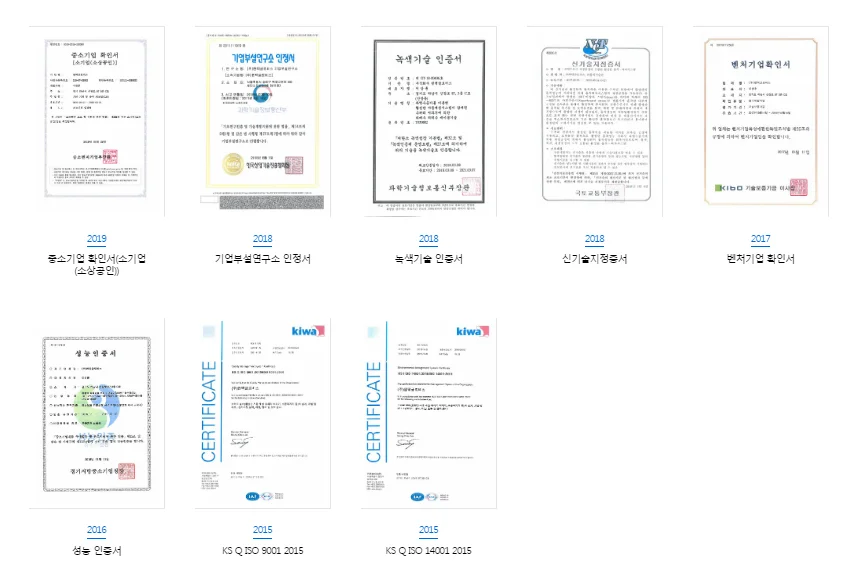

Certifications

Our Company

The world has been facing severe environmental problems, such as climate change and water shortage, due to rapid urbanization and industrial developments.

Increasing environmental issues have let human beings feel that clear water and fresh air is so precious, and there has been a paradigm shift to consider resources to recycle, not to use and throw away

Wintec Glovis contributes to recycling activated carbon which is a resource necessary to purify polluted water and air as a corporate that possesses the only technology to recycle eco-friendly activated carbon in the world.

We wiil grow up further as a global leading company to contribute to quality life of human beings in eco-friendly water and atmospheric treatment field through constant technical development ever after.

Thank you.

Efficient Carbon Regeneration Technology

Leveraging superheated steam at temperatures reaching 700C, the W-SCRS system provides rapid and uniform regeneration of activated carbon. Its advanced technology ensures depleted carbon is restored with minimal energy loss, making it ideal for water treatment facilities, gold extraction processes, and chemical manufacturing plants.

User-Friendly and Low Maintenance

Designed for hassle-free operation, the W-SCRS system features fully automatic PLC control, intuitive human-machine interfaces, and easily accessible maintenance panels. Centralized automatic lubrication and a low frequency of required servicing greatly reduce downtime and operational overhead.

Safety and Reliability Assured

Safety is paramount with overpressure protection, temperature cut-off, emergency stop, and water-cooled components. The robust stainless steel frame features an anti-corrosive finish for longevity, while the modular design suits both standard and custom plant layouts.

FAQs of W-SCRS Superheated Steam Carbon Regeneration System:

Q: How does the W-SCRS Superheated Steam Carbon Regeneration System work?

A: The W-SCRS system uses indirect superheated steam, heated up to 700C, to regenerate spent activated carbon. The system maintains optimal conditions via PLC automatic controls, providing consistent, high-quality regeneration in a safe, enclosed environment.Q: What are the main benefits of using this carbon regeneration system?

A: Key benefits include high regeneration efficiency, energy savings due to its advanced steam technology, easy operation via a fully automatic PLC, low maintenance demands, and robust safety features to protect both users and equipment.Q: Where can the W-SCRS system be installed and what industries is it suitable for?

A: This floor-mounted system can be installed in industrial settings worldwide and is particularly suited for water treatment plants, gold mining operations, and chemical processing industries that require regular activated carbon regeneration.Q: What safety measures are integrated into the system?

A: The W-SCRS includes overpressure protection, automated temperature cut-off, emergency stop functions, and water-cooling for safe operation during both batch and continuous processes.Q: When is maintenance required and how is it performed?

A: Maintenance is infrequent thanks to the centralized automatic lubrication and easily accessible panels. Users can quickly perform routine inspections and component servicing without dismantling the main system.Q: What is the typical capacity and what sizes of feed can be processed?

A: The system handles capacities up to 200 kg/h with input feed sizes up to 20 mm, supporting continuous or batch operation depending on plant requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese