W-SSCA Superheated Steam Carbon Adsorption

Product Details:

- Surface Finish Smooth

- Drive Type Electric Motor Driven

- Capacity 2500 Nm/h

- Size Standard

- Noise Level 80 dB

- Shape Rectangular

- Motor Power 5.5 kW

- Click to View more

W-SSCA Superheated Steam Carbon Adsorption Price And Quantity

- 100 Unit

W-SSCA Superheated Steam Carbon Adsorption Product Specifications

- Rectangular

- 5.5 kW

- Industrial Waste Gas Purification, VOC Gas Absorption

- Gray

- Superheated Steam with Carbon Adsorption

- 1500 kg

- 0.3 MPa

- Mild Steel

- Superheated Steam Carbon Adsorption

- 2500 Nm/h

- Powder Coated

- Standard

- 80 dB

- 50 kW

- Electric

- Smooth

- Electric Motor Driven

- Automatic

- 380 V

- 3600 mm x 1400 mm x 2200 mm

- High Adsorption Efficiency, Low Temperature Operation, Energy Saving

W-SSCA Superheated Steam Carbon Adsorption Trade Information

- South Korea

- Telegraphic Transfer (T/T)

- Export Standard Packing

Product Description

Product Description

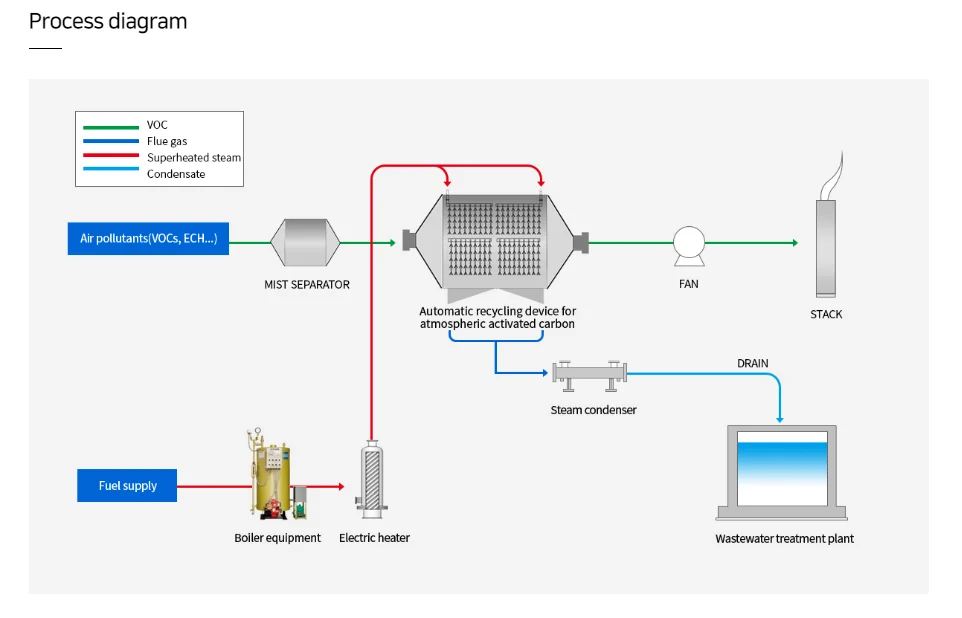

All-In-One activated carbon adsorption tower including adsorption and regeneration processes of air pollution control.

Product Features

Maximize reliability of air quality and system combined with A/C adsorption and A/C regeneration process

Easy operation and maintenance by A/C regenerating on site

Flexible response in case of high concentration inflow

Reduced operating costs with a regeneration system

Economical as operating cost is reduced by reusing regenerated activated carbon

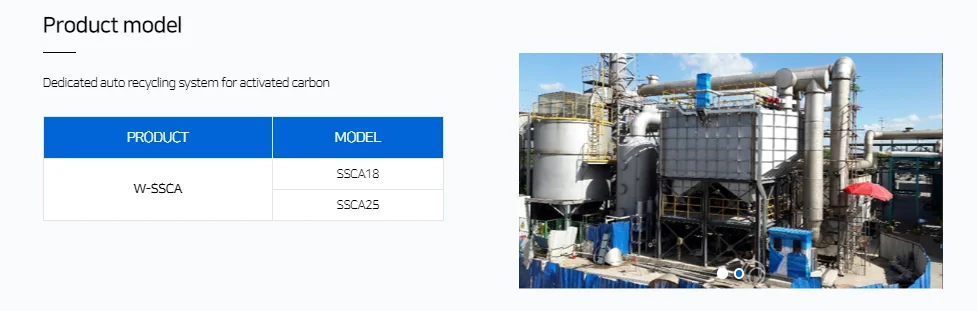

Model and Product

Product Name : W-SSCA

Model : SSCA 1600, SSCA 2100, SSCA 3200, SSCA 3600

Propose for product

Remove VOCs and odor control

Field of use

Any field where use Activated Carbon for example, steel plant, petrochemical plant, electrical and electronics semiconductor factory and leather & textile factory etc.

Certifications

Our Company

The world has been facing severe environmental problems, such as climate change and water shortage, due to rapid urbanization and industrial developments.

Increasing environmental issues have let human beings feel that clear water and fresh air is so precious, and there has been a paradigm shift to consider resources to recycle, not to use and throw away

Wintec Glovis contributes to recycling activated carbon which is a resource necessary to purify polluted water and air as a corporate that possesses the only technology to recycle eco-friendly activated carbon in the world.

We will grow up further as a global leading company to contribute to quality life of human beings in eco-friendly water and atmospheric treatment field through constant technical development ever after.

Thank you.

Advanced Control for Reliable Operation

Equipped with a PLC automatic control system, the W-SSCA ensures precise adsorption processes and seamless regeneration cycles. The intelligent management decreases manual intervention and enhances overall system stability, making this solution suitable for continuous industrial use.

High Adsorption Efficiency and Longevity

With a multi-stage carbon adsorption bed, the machine achieves an impressive 95% adsorption efficiency. Designed for easy maintenance and longevity, the carbon bed typically lasts between 1 and 2 years, with straightforward, steam-based regeneration.

Versatile Industrial Applications

Engineered for industrial waste gas and VOC purification, the W-SSCA unit operates effectively in demanding environments. Its power-saving features and robust build make it ideal for factories, large plants, and facilities seeking reliable air treatment solutions.

FAQs of W-SSCA Superheated Steam Carbon Adsorption:

Q: How does the W-SSCA Superheated Steam Carbon Adsorption system operate?

A: The system uses superheated steam to activate carbon beds in a multi-stage process, efficiently adsorbing harmful gases from industrial exhaust streams. A PLC automatic control system manages its cycles for optimal performance.Q: What is the expected carbon bed life, and how is regeneration performed?

A: The carbon bed typically lasts 1 to 2 years under regular operating conditions. Regeneration is accomplished using steam, restoring the carbons adsorption efficiency without manual replacement.Q: When should maintenance be performed on the W-SSCA unit?

A: Maintenance needs are minimal due to its automatic controls and lubrication system. Periodic inspections are recommended, typically aligned with scheduled plant maintenance or when exhaustion of carbon bed life is approaching.Q: Where is the W-SSCA unit installed, and what are the space requirements?

A: The unit is designed for floor mounting in industrial environments. Its standard dimensions (3600 mm x 1400 mm x 2200 mm) and rectangular shape require adequate space for installation and access for operation and servicing.Q: What process ensures high adsorption efficiency in the W-SSCA unit?

A: A multi-stage carbon adsorption bed combined with superheated steam technology enables the system to reach adsorption efficiencies of 95% or higher, making it highly effective for gas purification.Q: How is the system beneficial for industrial air purification?

A: The W-SSCA offers reliable removal of VOCs and waste gases, energy-efficient operation, low noise emission (80 dB), and minimal maintenance, resulting in improved workplace safety and compliance with environmental standards.Q: Can the W-SSCA operate in varied environmental conditions?

A: Yes, the system works efficiently in environments with temperatures ranging from 5 to 40C and humidity below 85%. Its robust design and powder-coated finish also ensure corrosion resistance and durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese