4flutes Corner Radius Carbide End Mills for Sus Stainless Steel

Product Details:

- Shape End Mill with Corner Radius

- Size Available from 1mm to 20mm diameter

- Noise Level Low (Depends on machine conditions)

- Drive Type Machine Driven, Collet Chuck Mounted

- Diameter 1mm to 20mm

- Usage & Applications Milling of SUS Stainless Steel, Alloy Steels, Hard Materials

- Capacity High-speed Cutting, High Feed Rate

- Click to View more

X

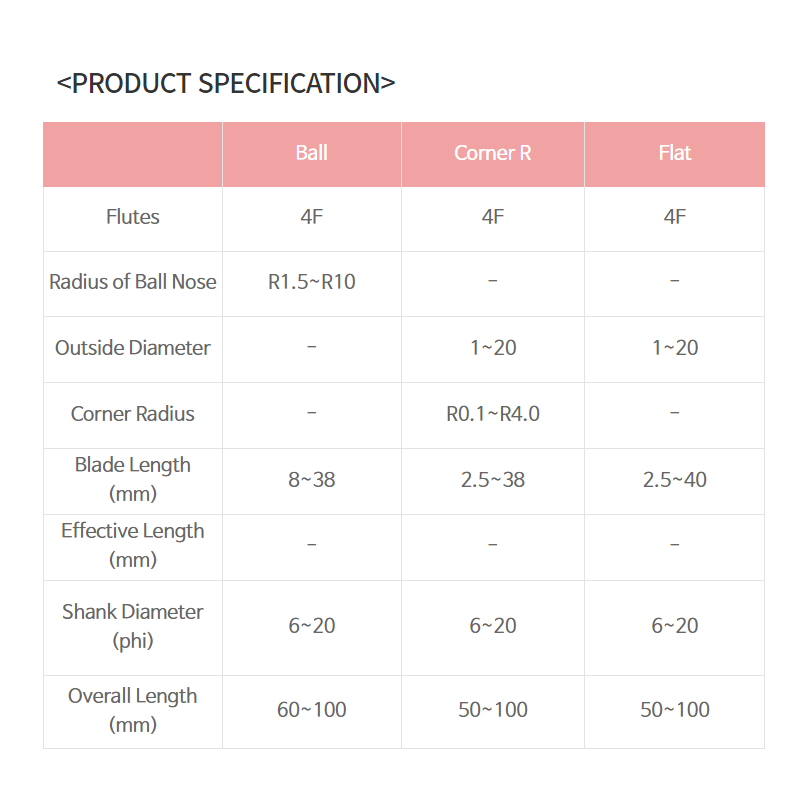

4flutes Corner Radius Carbide End Mills for Sus Stainless Steel Product Specifications

- Milling of SUS Stainless Steel, Alloy Steels, Hard Materials

- Metallic Grey, Blue Tint (Coated)

- High-speed Cutting, High Feed Rate

- High hardness, Superior toughness, Enhanced tool life, Corner radius for breakage resistance

- Varies (Refer Size Specifications)

- Ultra-fine grain solid carbide

- Varies by size

- Mirror Finish, High Smoothness

- External Coolant Recommended

- 4 Flutes Corner Radius Carbide End Mill

- Available from 1mm to 20mm diameter

- End Mill with Corner Radius

- Low (Depends on machine conditions)

- Precision Ground, Nano Coating

- Nano Coated, Polished

- Machine Driven, Collet Chuck Mounted

- Manual, CNC Machine Operated

- 1mm to 20mm

Product Description

Product Description

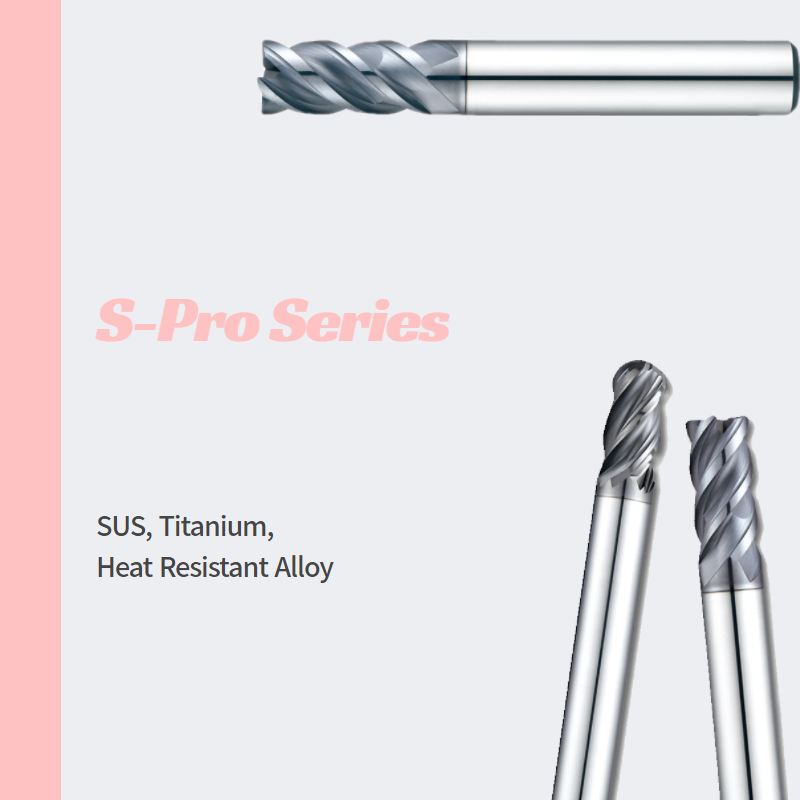

4 Flutes Ball End Mills for Stainless steels, titanium

- Geometry design to protect the chattering

- Unique flute design to improve chip flow

- Excellent Surface roughness by 4 flutes, smooth chip flow with big chip pocket

- Outstanding performance for Alloy steels, SUS, Titanium, Inconel and hard to cut materials

Company Information

We have been striving for professional manufacturer of MILLING BUR which keeps the same quality from a batch to another batches. Lean process makes it possible to be a competitive in cost and lead time. Intensive development was resulted in broad range tools to fit in many different machine types. We believe that these achievements contribute customers to reach their objective.

The competence of HANSONG M&T is developing and manufacturing END MILL and MILLING BUR. The company will continue the focus on these core technologies to keep the position of professional manufacturer.

Engineered for Stainless Steel Excellence

Designed to withstand the harsh demands of machining stainless steels, these end mills offer unmatched durability, thanks to their nano coating and ultra-fine grain carbide construction. The optimized helix angle and corner radius reduce tool breakage and improve performance, making them ideal for a wide range of milling applications in industrial environments.

Precision and Versatility Across Applications

Whether you are roughing, semi-finishing, or finishing, these end mills provide remarkable control and surface quality. Their straight shank and compatibility with standard collet chucks ensure easy setup on both CNC and manual machines. Customizable features and a wide diameter range (1mm to 20mm) ensure a perfect fit for intricate tasks or heavy-duty production runs.

Enhanced Tool Life and Smooth Chip Evacuation

Advanced nano coating, mirror finish, and precision ground flute geometry maximize resistance to wear and heat. Effective chip evacuation is achieved through the optimal helix design, reducing the risk of tool clogging and contributing to lower operational noise. The result is consistently extended tool life and reliable performance at higher feed rates.

FAQs of 4flutes Corner Radius Carbide End Mills for Sus Stainless Steel:

Q: How does the helix angle of 35 to 45 benefit machining stainless steel with these end mills?

A: The helix angle of 35 to 45 promotes efficient chip evacuation, reducing the likelihood of stainless chips clogging the flutes. This design minimizes heat buildup and ensures smoother operation, critical for preventing work hardening and tool wear during stainless steel machining.Q: What materials are these end mills best suited for?

A: These end mills are tailor-made for SUS 304, SUS 316, and other stainless steels. They also provide excellent results on alloy steels and hard materials up to HRC 55-60, making them versatile for demanding industrial milling applications.Q: When should I choose a corner radius end mill over a standard square end mill?

A: A corner radius end mill is preferred when machining tough or hard materials, as the rounded corner reduces the likelihood of chipping and tool breakage. This makes them ideal for extended tool life and improved surface finishes, particularly when working on stainless and hardened steels.Q: Where can these end mills be used?

A: These tools are compatible with both CNC and conventional milling machines across industries such as aerospace, automotive, medical device manufacturing, and general engineeringanywhere precision milling of stainless steels or hard alloys is required.Q: What is the process for selecting the appropriate corner radius and diameter for my application?

A: Evaluate your part geometry and required surface finish. A larger corner radius (up to 2 mm) enhances tool strength and longevity in roughing, while smaller radii (as low as 0.2 mm) offer finer detail and surface finish in finishing applications. Select diameters from 1mm to 20mm based on your machine setup and feature sizes.Q: How does using a nano-coated, ultra-fine grain carbide end mill benefit tool performance and longevity?

A: Nano coating protects the tool from oxidation and heat, while ultra-fine grain carbide offers exceptional hardness and toughness. Combined, these properties substantially extend tool life, reduce wear, and support higher-speed operations with consistently smooth surface finishes.Q: What cooling or lubrication system is recommended during machining?

A: External coolant is recommended when using these end mills. Effective lubrication helps to dissipate heat, maintain tool integrity, and further improve tool life and surface finish quality during high-speed cutting.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese