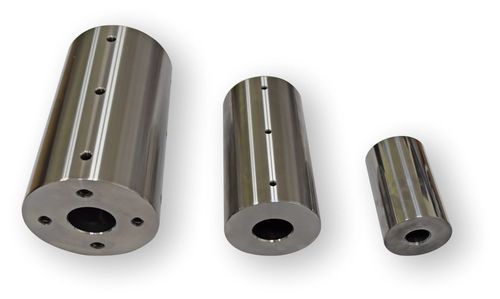

Wheel Nut

Product Details:

- Capacity Standard for Automotive Use

- Usage & Applications Automobile Wheels, Truck or Car Wheel Fitting

- Features High Tensile Strength, Anti-Rust, Durable

- Drive Type Hex Drive

- Shape Hexagonal

- Diameter 12mm, 14mm (other as required)

- Size M12, M14, other sizes available

- Click to View more

Wheel Nut Price And Quantity

- 1 Unit

Wheel Nut Product Specifications

- Forged

- Standard for Automotive Use

- Automobile Wheels, Truck or Car Wheel Fitting

- High Tensile Strength, Anti-Rust, Durable

- Silver

- Varies as per Size (customizable)

- Hex Drive

- Manual

- Hexagonal

- Approx. 30-60 g (depending on size)

- Wheel Nut

- 12mm, 14mm (other as required)

- Steel

- M12, M14, other sizes available

- Smooth, Corrosion Resistant

- Zinc Plated

Product Description

Product Description

Company Profile

Combining leading edge tech. and PUNGKANG Co Ltds unique know how, an Enterprise that creates the future of Automotive parts industry. PUNGKANG Co Ltd was established in 1974 as an enterprise which professionally manufactures Nuts for Automotive industry. Together with the continuous development of the Korean automotive industry over the past 48 years, PUNGKANG Co Ltd has taken root deeply thru. unceasing efforts as an enterprise specializing in automotive parts that produces Nuts and Forged products and supplies to domestic overseas automotive companies which satisfy high technology and quality level of the automobile industry.

Currently, global automotive industry is innovatively changing from fossil fuels into electric and hydrogen fuels and is moving forward day by day with the integration of super innovative technology. In line with these rapid changes, PUNGKANG Co Ltd developed new tech. products to apply to EV batteries and light weight vehicles by striving for overseas technology alliances on our own, and these earnest efforts bore fruit, making the way for parts supply to the world prominent automotive corporations as well as domestic major OEMs.

We are full of confidence in our leading edge technology, creative know how and unparalleled high quality system and state of the art test equipment thru. half century accumulated craftsmanship since establishing, so that there is nothing lacking to supply our strictly confirmed products that surely satisfy new customer trends and requirements. In future, continuously PUNGKANG Co Ltd shall keep our clients trust by supplying high quality products based upon innovative technology and process system. We sincerely request for your generous guidance and support

Precision Engineering for Safety and Reliability

Each wheel nut is produced using advanced forging technology and coated with a zinc plated, corrosion-resistant layer. With rigorous standards, including a minimum tensile strength of 800 MPa, these wheel nuts offer secure fitment and long-lasting durability for automotive applications.

Customizable Dimensions for All Vehicle Types

Wheel Nuts are offered in multiple sizes, including M12, M14, and custom diameters, adaptable to your specific vehicle requirement. Our flexible options cover various thread pitches and packaging, ensuring a perfect solution for cars, trucks, and commercial vehicles.

Applications and Advantages of Zinc Plated Wheel Nuts

Widely used for automobile wheels and truck fittings, these nuts provide robust anti-rust properties and high tensile strength. Their smooth finish and reliable performance make them the preferred choice for automotive professionals and aftermarket suppliers.

FAQ's of Wheel Nut:

Q: How do I select the correct thread pitch and size for my vehicle's wheel nuts?

A: Determine the existing thread size and pitch on your vehicle-common pitches are 1.25mm, 1.5mm, and 1.75mm, with sizes like M12 or M14. Consult your vehicle's manual or a professional mechanic to match the correct specification for safe, proper fitment.Q: What are the benefits of using forged steel wheel nuts with zinc plating?

A: Forged steel ensures superior strength (minimum 800 MPa), while zinc plating provides outstanding corrosion resistance, enhancing both the security and longevity of wheel installations, especially in challenging weather conditions.Q: When is it recommended to replace wheel nuts on my vehicle?

A: Replace wheel nuts when they display signs of corrosion, thread damage, or wear. Regular inspections during tire changes or routine maintenance can help ensure continued safety and prevent wheel detachment.Q: Where can these wheel nuts be used?

A: These wheel nuts are suitable for a broad range of applications, including cars, trucks, and light commercial vehicles. Their customizable sizes and robust construction make them ideal for automotive professionals and commercial fleets.Q: What is the process for installing these wheel nuts manually?

A: Align the wheel and wheel nut threads, screw the wheel nuts by hand, then use a manual hex drive wrench to tighten them evenly and securely, following the vehicle manufacturer's recommended torque settings.Q: How does the closed-end, hexagonal design benefit wheel installations?

A: A closed-end design safeguards threads against dirt and moisture, while the hexagonal shape allows easy tightening and removal with standard tools, minimizing installation time and effort.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese