Poultry Farm Control Box Hanaro System

Product Details:

- Connector Type Terminal block

- Insulation Material PVC Insulated Wiring

- Feature Microprocessor based, Auto-manual mode, Alarm indicator, Real time display

- Shape Rectangular

- Efficiency >92%

- Humidity % 95%

- Overheating Protection YES

- Click to View more

Poultry Farm Control Box Hanaro System Price And Quantity

- 1 Set

Poultry Farm Control Box Hanaro System Product Specifications

- Standard - Customizable

- Rectangular

- White & Blue

- Microprocessor based, Auto-manual mode, Alarm indicator, Real time display

- PVC Insulated Wiring

- Terminal block

- 95%

- 7.5 kg

- Poultry Farm Control Box

- Wired

- 220V AC

- 50-60 Hz

- >92%

- Metal enclosure with ABS front panel

- YES

- Relay output

- 1

- 400 x 250 x 150 mm

- Poultry Farm Automation

- IP54

- 220-240 V

- Powder Coated

- Surge, Short circuit, Overload

- -10C to +55C

- Wall Mounted

- 0.98

- Low power consumption

- Single phase

Product Description

Venco Korea

Industries worldwide change rapidly. What could be changed over a hundred years in the past would take only one year now. Sooner, we would even feel that things would be remembered as things in the far distant past. Growing over an area where we can transcend time and space, the livestock industry has grown also by leaps and bounds. Is it extravagant?

What lies beneath the development of livestock industry is creative research and faithful efforts of the driven people with dreams.

We could live without cars or mobile phones. But, is there any person who could live without eating? The food industry has been globalized and positioned as the 6th industry in the market. It is a task of history for us to love and prime the livestock industry that takes the lion share of the food industry. The livestock industry is a solid vision as a core industry in the future. Considering that, the people of Venco Korea will not be complacent with the current trend and will make more efforts to innovate quality, technology, and prices for the day where all of us feel pleased.

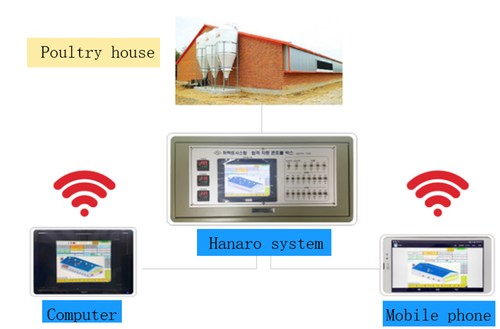

Efficient Farm Monitoring and Control

The Hanaro System utilizes a digital LED display and microprocessor-based automation to oversee essential environmental factors in poultry houses. Operators can set and monitor temperature, humidity, lighting schedules, and more with effortless precision, ensuring optimal conditions for livestock health and productivity.

Intelligent Alarm and Protection

With both audible and visual alarm outputs, the control box immediately alerts operators to any irregularities such as overheating or electrical issues. Protection features guard against surges, short circuits, and overloads to maintain consistent operation and safety within the farm.

Robust and Versatile Design

Designed for rigorous poultry farm demands, the system offers a metal enclosure with ABS front panel, IP54 rating, and wall-mounted installation. Its adaptable size and customizable connection simplify integration into various farm infrastructures, supporting efficient long-term use.

FAQ's of Poultry Farm Control Box Hanaro System:

Q: How does the digital LED display improve poultry farm management?

A: The digital LED display provides real-time data on temperature, humidity, and timer settings, allowing operators to make immediate adjustments and ensure the optimal environment within the poultry house.Q: What processes can the Hanaro Control Box automate on a poultry farm?

A: The system automates fan operation, heating, lighting schedules, and water supply, reducing manual intervention and promoting consistent care for poultry throughout the day.Q: When should I use the alarm output feature?

A: Operators should rely on the alarm output-both audible and visual-whenever the system detects issues such as overheating, electrical faults, or deviations from preset parameters to address problems before they affect livestock.Q: Where is the best mounting location for the Hanaro Control Box?

A: For optimal functionality, the control box should be wall-mounted in a central, easily accessible location within the poultry farm, ensuring straightforward monitoring and control while maintaining safety standards.Q: What are the benefits of EEPROM memory backup during power failures?

A: EEPROM memory backup ensures all settings and data are retained during power outages, so the system resumes normal operations without losing critical control parameters, reducing downtime and risk.Q: How do I configure the system for customized poultry house requirements?

A: Users can adjust key parameters such as temperature, humidity, lighting schedule, and operating modes directly through the display panel to tailor the system's operation to specific farm needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

![[POREST N] Leaf](https://cpimg.tistatic.com/09584125/b/4/-POREST-N-Leaf.png?tr=w300)