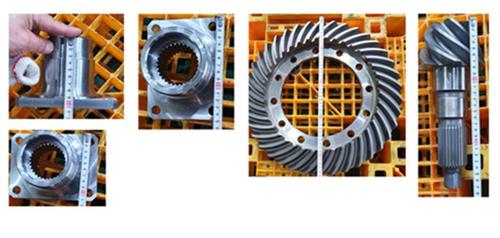

Reverse Engineering Gear

Product Details:

- Hardness 58-62 HRC

- Power Source Mechanical

- Dimension (L*W*H) 120 mm x 120 mm x 22 mm

- Feature High Durability, Corrosion Resistant Finish

- Usage & Applications Transmission Systems, Power Transfer Mechanisms

- Size Custom/Standard Options

- Diameter 120 mm

- Click to View more

Reverse Engineering Gear Price And Quantity

- 1 Unit

Reverse Engineering Gear Product Specifications

- 2.8 kg

- Direct Fit

- 120 mm

- 22 mm

- CNC Machined

- Alloy Steel

- Reverse Engineering Gear

- Mechanical

- 58-62 HRC

- Trucks, Heavy Equipment

- High Durability, Corrosion Resistant Finish

- 120 mm x 120 mm x 22 mm

- Transmission Systems, Power Transfer Mechanisms

- Custom/Standard Options

- 120 mm

- Universal Fit (Customizable)

- High Torque Capacity

Reverse Engineering Gear Trade Information

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

Product Description

Currently, the production and supply of reverse design products such as industrial vehicles such as forklift, machine tools, industrial machinery, hypoid gears used in steel mills, and bevel gears are increasing.

Duson International Korea boasts the world's best low-cost gear supply in reverse design product development.

Product Feature

Spec: BUYERS STANDARDS

Product Specification

Spec : BUYERS STANDARDS

Product Use

Automotive parts

Our Company

DUSON INTERNATIONAL CO., LTD.

Starting with the press mold of the Japanese automotive plate press component makers, plastic prototype component makers , Interior decoration component makers, hypoid gear, bevel gear in charge of manufacturing inspection tools, transport devices, etc. and preparing for production in world wide car makers.

Precision Craftsmanship for Demanding Applications

Our gears are engineered using advanced CNC machining and precision finishing, delivering supreme accuracy and reliability. Case-hardened and ground surfaces ensure exceptional wear resistance and optimal performance in harsh environments, making them an ideal choice for power transfer in trucks, heavy equipment, and other industrial applications.

Fully Customizable Specifications

We offer an extensive range of modules (1.512), tooth profiles, dimensions, and finishes to suit every clients needs. Whether you require a standard or tailor-made gear, our reverse engineering process and flexible manufacturing enable us to deliver gears precisely to your required measurements, ensuring compatibility and performance.

Engineered for Longevity and Efficiency

Manufactured from premium alloy steel and featuring anti-rust coatings, our gears provide high durability and resistance to corrosion. Heat treatment ensures a hardness of 5862 HRC, supporting operations in temperatures from -20C to +180C while maintaining low noise and high torque transfer.

FAQs of Reverse Engineering Gear:

Q: How does the reverse engineering process work for these gears?

A: Reverse engineering starts with analyzing and measuring an existing gear or assembly. Using advanced metrology and CAD software, we recreate accurate 3D models, refine them to match or improve upon original specifications, and then manufacture the new gear using CNC machining, precision heat treatment, and custom finishing to ensure seamless integration.Q: What applications are these gears suitable for?

A: These gears are designed for use in transmission systems and power transfer mechanisms, particularly in trucks, heavy equipment, and other industrial vehicles. Their robust construction and customizable features make them ideal for a range of demanding mechanical and automotive applications.Q: When should I consider replacing gears with reverse engineered versions?

A: Consider reverse engineered gear replacement when original gears are worn, discontinued, or when you require upgraded performance or customization. This approach ensures compatibility, restores function, and can extend equipment life even if original parts are no longer available.Q: Where can I use these reverse engineered gears?

A: These gears are versatile and suitable for direct fit in various vehicle models and industrial machineryespecially within environments requiring high torque capacity, such as logistic trucks, construction equipment, and heavy-duty power transfer systems.Q: What manufacturing processes ensure the gears durability and precision?

A: Our gears undergo rigorous CNC machining for fine tolerances, followed by case hardening and precision grinding to achieve the desired hardness (5862 HRC) and smooth surface finish. An anti-rust coating adds extra protection, supporting long-term durability in challenging environments.Q: How are the gears packaged and delivered to ensure quality?

A: To maintain quality during transit, gears are securely packaged in corrugated boxes or wooden crates, safeguarding them from mechanical damage and environmental exposure during distribution, export, or storage.Q: What are the key benefits of choosing these gears for your application?

A: Key advantages include high torque capacity, reduced operational noise, exceptional longevity due to heat treatment and surface finishing, corrosion resistance, and the ability to tailor each gear to exact requirements for direct installation and reliable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese