REPRE PVC compound

Product Details:

- Tensile Strength 12 MPa

- Surface Finish Smooth

- Melting Point 165C

- UV Resistant Yes

- Plastic Type Flexible PVC

- Density 1.40 Gram per cubic centimeter(g/cm3)

- Heat Resistance Yes

- Click to View more

REPRE PVC compound Price And Quantity

- 10000 Kilograms

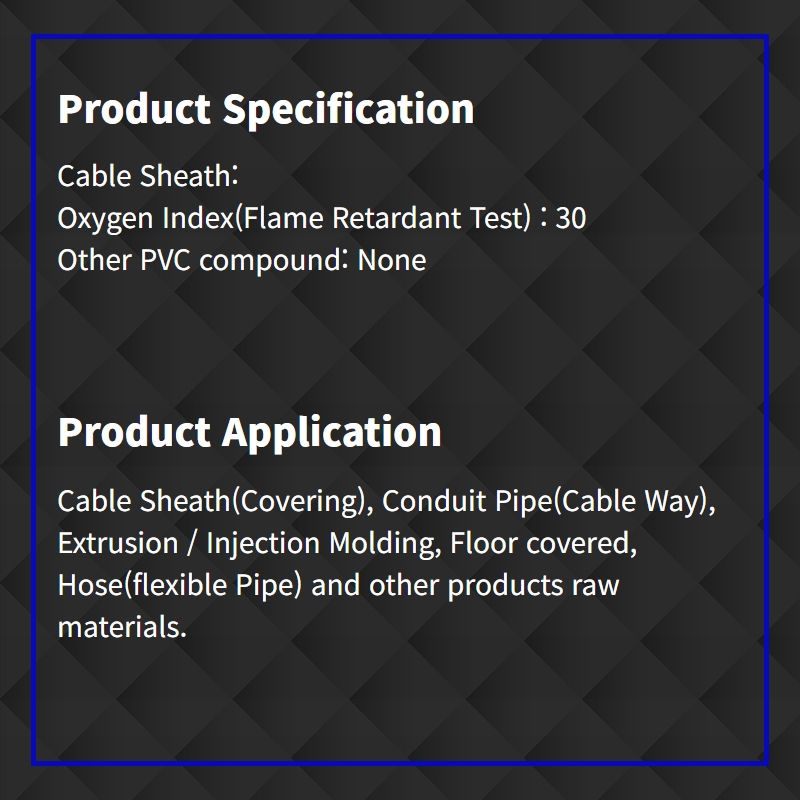

REPRE PVC compound Product Specifications

- Yes

- 165C

- Polyvinyl Chloride

- 65 Shore A (customizable)

- Flexible PVC

- Thermoplastic

- Extrusion, Injection Molding

- 12 MPa

- Smooth

- Customizable

- Grey

- 25 kg (standard bag)

- Solid

- Yes

- Granule

- Yes

- PVC Compound

- 1.40 Gram per cubic centimeter(g/cm3)

REPRE PVC compound Trade Information

- 500kg Bulk Bag

Product Description

Product Description

Our Company

Dooyoung Metal was founded in 1996 and was initially founded as a recycling company that collects waste wires and sells wire sheathing and copper separately. In 1998, after obtaining approval for comprehensive recycling processing, we have developed into a company that collects obsolete and defective wires and sells PVC, EPS and PE. To that end, Dooyoung Metal appoints an environmental manager and carries out the modernization of its business equipment every year. The company has established a technical research center for the first time in its kind, and is in the process of researching and completing chemical recycling methods that go beyond traditional mechanical recycling. Dddyoung Metal will strive for Upcycling beyond Recycling and will continue to strive for customer satisfaction and the preservation of the global environment.

Advanced Electrical & Safety Performance

Designed with high dielectric strength and low volatile matter, the REPRE PVC compound excels in electrical insulation for wires and cables. Flame-retardant properties are available if requested, ensuring safety standards in critical environments. Leak protection and UV resistance add further layers of reliability in harsh conditions.

Customizable & Eco-Conscious Material

REPRE PVC compound stands out with customizable hardness (65 Shore A standard), granule size, and formulation options like phthalate-free for environmental protection. It is fully recyclable and RoHS compliant, supporting sustainable manufacturing practices. Its smooth, solid grey finish suits various design preferences in multiple industries.

Flexible Processing and Application Range

Suited for both extrusion and injection molding, this thermoplastic compound handles processing temperatures from 150C to 190C. With an elongation at break of 300% and tensile strength of 12 MPa, it adapts to the precise demands of footwear, automotive, and cable products. Custom bag sizes and expert distribution are available to meet diverse project needs.

FAQ's of REPRE PVC compound:

Q: How is REPRE PVC compound processed during manufacturing?

A: REPRE PVC compound is processed using extrusion or injection molding techniques at recommended temperatures of 150C to 190C. This thermoplastic material flows smoothly for shaping into wires, cables, footwear parts, and profiles.Q: What makes REPRE PVC compound suitable for electrical applications?

A: Its high dielectric strength, along with reliable heat resistance up to 80C and low volatile matter ( 0.5%), qualifies the compound for use in electrical insulation, especially in wires and cables requiring enhanced safety.Q: When should a flame-retardant version of the REPRE PVC compound be requested?

A: You should request the flame-retardant option when your application demands additional protection against fire, such as in electrical, automotive, or building profiles exposed to elevated risk environments.Q: Where is REPRE PVC compound typically used?

A: This compound is widely utilized in manufacturing wires and cables, profiles, shoe components, and automotive materials due to its flexible and durable properties.Q: What are the environmental benefits of REPRE PVC compound?

A: REPRE PVC compound supports eco-friendly practices as it is recyclable and available in a phthalate-free formulation. It also meets RoHS compliance, ensuring minimal impact on the environment.Q: How does customizing hardness or length enhance product versatility?

A: Customizing the hardness (65 Shore A standard, adjustable) and length allows adaptation of the compound for specific applications, ranging from soft footwear soles to durable automotive seals, optimizing performance and comfort.Q: What storage conditions are recommended for REPRE PVC compound?

A: It should be stored in a cool, dry place to preserve material integrity and maintain its key properties, preventing moisture absorption and degradation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese