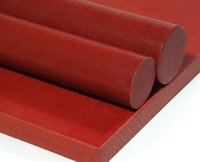

PTFE engineering plastic

Product Details:

Product Description

Product Introduction

Product Use

- Chemical equipments

- General facilities

- Industrial parts

Company Profile

Ilwoong Platech

Since our founding in 1988, we have been devoted to professional quality control, localization of imported products, technology development and facility investment with the aim of supplying the best quality engineering plastic products to our customers at the best price. As a result, we have been recognized for quality and technology in various types of engineering plastic such as PTFE business, extrusion & UHMW-PE business, MC Nylon business, PVC business, finished product processing business.

We are a company that produces materials with recognized quality from engineering plastic distribution in Korea. We have grown to become a company that localizes the imported products, and exports to other countries around the world. Ilwoong Platech Engineering Plastic is growing into a world-class engineering plastic company through steady growth of existing businesses and efforts to pursue new values.

Exceptional Chemical and Thermal Stability

PTFE Engineering Plastic maintains robust performance even when exposed to extreme temperatures from -200C to +260C. Its excellent resistance to almost all chemicals makes it the material of choice for aggressive industrial settings. With superior flammability ratings and a smooth, non-stick surface, PTFE remains stable where traditional plastics might fail.

Versatility Across Diverse Applications

Available in sheet, rod, and tube forms, PTFE Engineering Plastic is engineered for flexibility. Its hallmark properties-including a low coefficient of friction, negligible water absorption, and superior dielectric strength-enable its use in electrical insulation, chemical processing, machine components, and sealing solutions.

FAQ's of PTFE engineering plastic:

Q: How does PTFE Engineering Plastic perform in harsh chemical environments?

A: PTFE exhibits excellent chemical resistance, making it suitable for almost any industrial or laboratory environment. It resists corrosion, degradation, and reaction to virtually all chemicals, acids, and bases, ensuring reliable long-term performance in aggressive settings.Q: What is the typical process for shaping and machining PTFE into sheets, rods, and tubes?

A: PTFE is processed through molding and extrusion techniques. After initial molding, CNC machining or cutting can refine the material into precise dimensions for sheets, rods, or tubes, allowing customization for specific industrial applications.Q: Where is PTFE Engineering Plastic commonly used, and what are its primary benefits?

A: PTFE is widely used in chemical processing plants, electrical applications, and machinery requiring superior insulation or low-friction operation. Its durability, high operating temperature range, and nearly universal chemical resistance provide significant advantage in these fields.Q: When should I consider using PTFE over other engineering plastics?

A: Opt for PTFE when your application demands extreme resistance to chemicals and temperature, or when you require a low coefficient of friction. PTFE is also ideal where insulation properties and minimal water absorption are necessary.Q: What are the advantages of PTFE's surface finish and low water absorption?

A: PTFE's exceptionally smooth surface minimizes friction and prevents material build-up, which is critical in gaskets and seals. Its low water absorption (<0.01%) ensures stability and dimensional integrity in humid or submerged conditions.Q: How should PTFE Engineering Plastic components be maintained to maximize lifespan?

A: PTFE components require minimal maintenance thanks to their chemical inertness and non-stick properties. Regular inspection for mechanical wear in high-stress applications is suggested, but PTFE's self-lubricating surface naturally reduces the risk of damage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese