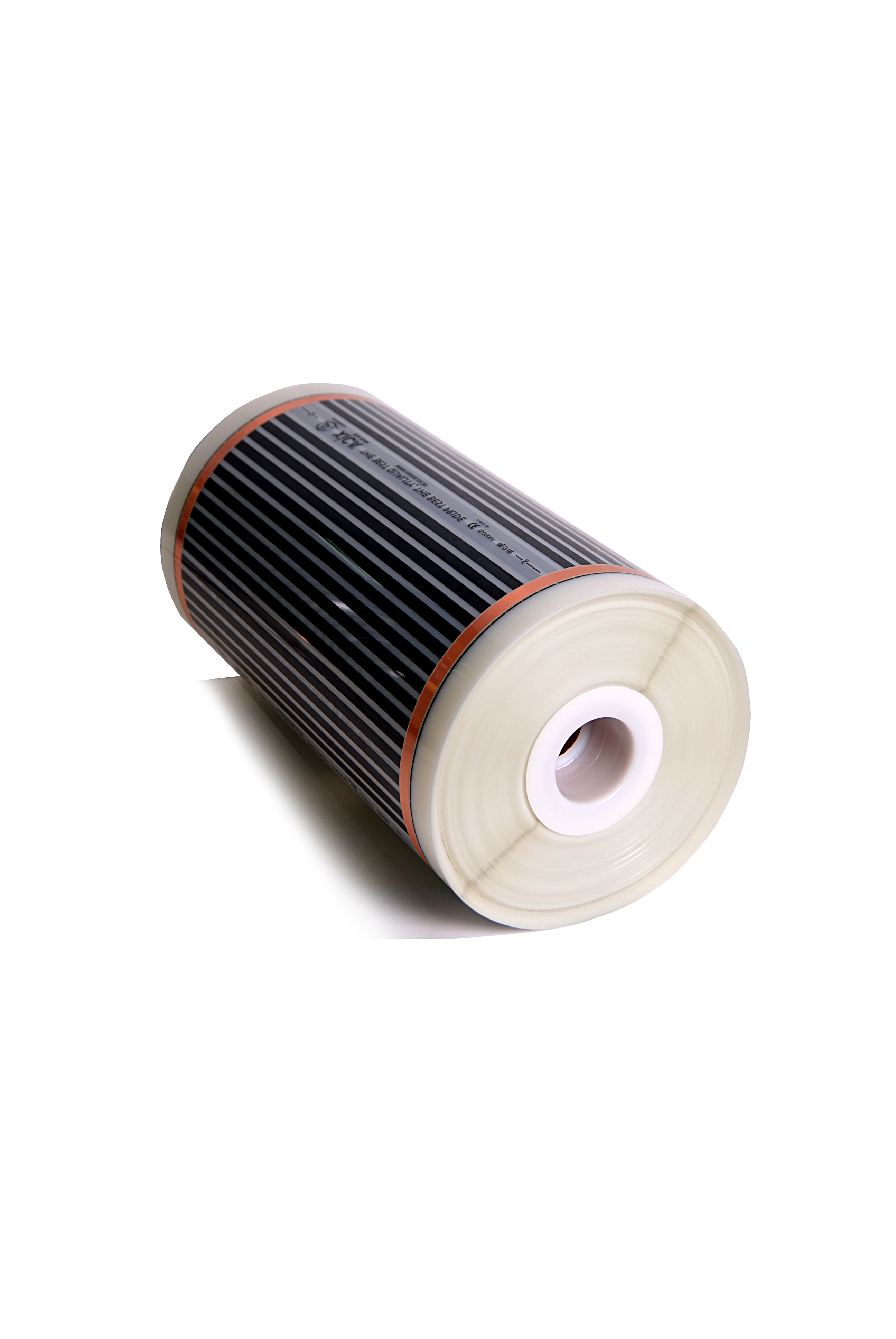

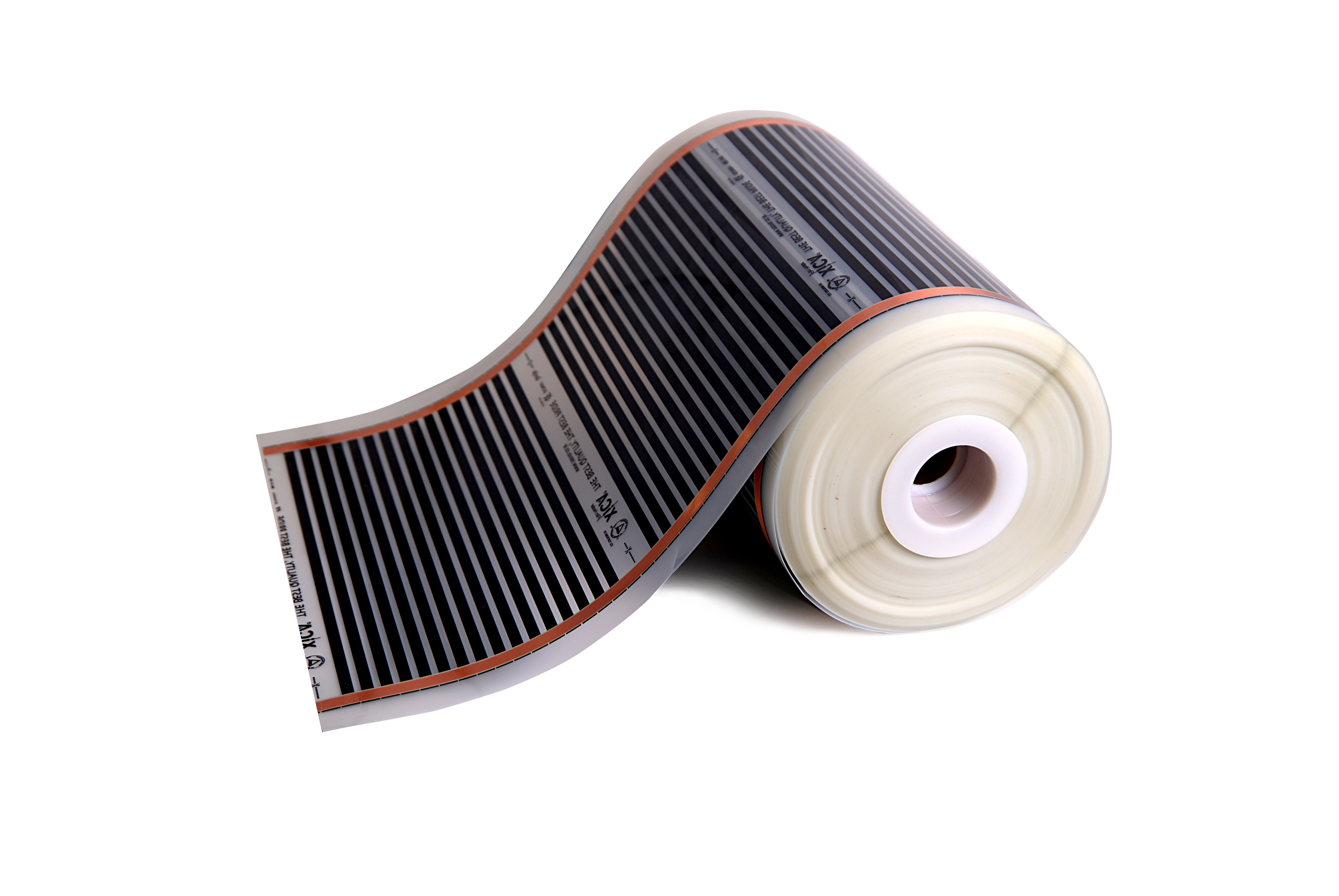

PTC Heating film (heating film xica ptc two layer printing insulator anti-flammable)

Product Details:

- Purity High Purity Carbon Paste

- Thickness 0.338 mm

- Form Flexible Film

- Usage Underfloor heating, wall heating, snow melting

- Features Self-limiting temperature, Short-circuit resistant, Overheat protection, Durable

- Application Indoor Heating Systems, Floor Heating, Wall Heating

- Machines Type Compatible with Heating Panels, Infrared Heaters

- Click to View more

PTC Heating film (heating film xica ptc two layer printing insulator anti-flammable) Price And Quantity

- 1500 Meter

PTC Heating film (heating film xica ptc two layer printing insulator anti-flammable) Product Specifications

- Flexible Film

- Underfloor heating, wall heating, snow melting

- Self-limiting temperature, Short-circuit resistant, Overheat protection, Durable

- Indoor Heating Systems, Floor Heating, Wall Heating

- Approx. 0.25 kg/m

- Customizable (Standard: 250mm x 1000mm)

- 0.338 mm

- Polyimide + Carbon/PET

- High Purity Carbon Paste

- Self-regulating, Anti-flammable, Thin Film

- PTC Heating Film

- Rectangular Sheet

- 100-240V (as per customization)

- Direct Surface Installation, Underfloor/Floor Mount

- Black/Transparent with Printed Layers

- N/A (Sheet/Film Type)

- Flame Retardant, Electrical Insulation Grade

- Compatible with Heating Panels, Infrared Heaters

- Double Layer Printing

Product Description

[XiCA: Heating Film]

XICA Sublimates the stability of heating film to golbal standards

associated with a given temperature change. The planar heating element is heated by the current flowing through itself. If the power supplied and the amount of heat radiated are the same, it will maintain a certain temperature range regardless of the external temperature.

When the heating element becomes overheated by the external temperature, the resistance value increases rapidly, and the current value decreases to prevent overheating of the electric device.

XICA Application

- Industrial Parts and materials

- Building, construction,floor,wall etc

- High- temperature sauna, snow melting

- Portable heating elements, hand warmer

Straight Type Silver Bus Bar Merit

The structural merit of this type is it can prevent sparks and reduce the production cost because of the smaller surface contact area of the silver bus bar and copper strip.

The disadvantage is that the silver bus bar has a high resistance in proportion to the printing area, so it is difficult to conduct electrical energy. Therefore, when the cold winter temperature is low, the amount of current passing through is small, so the amount of heat is also reduced.

Uniform temperature distribution and stable resistance change rate by uniform carbon coating- Self developed technology to print uniform density carbon ink

- Printing Technology by patented equipment to print uniform carbon coating

- Development of special laminating equipment for heating film

- World-class quality insulation, flame retardant PET film

- Special silver busbar mold design prevents sparks on the carbon surface.

- overheating dispersion design in the center of heating film with special printing technology

- Use of Laminex film which has strong resistance against transformation due to heat.

XiCA pursues the best technology and quality stabilization

Sparks can occur in the heating film because of various factors. Most of them are caused by the air layer between the copper bus bar and base film.

Therefore, the most important for the laminating equipment and heating film technology is to remove the air layer during the manufacture of the heating film.

[XiCA application]

The XiCA heating film series can be applied:

- Industrial parts and materials

- Office, building, wall, floor...

- High-temperature sauna, and snow melting

- Portable heating element

[Product Specification]

- Customized manufacturing is available

- Tinned Copper Busbar, 0.275mm Product and other product from mentioned above is possible by order.

- XM type Heating film uses 2nd grade anti flammable electricity insulated Milky PET film approved by UL94. XT type uses transparent PET film.

Advanced PTC Heating Technology

Engineered with Positive Temperature Coefficient (PTC) properties, this heating film delivers self-regulating warmth, meaning it automatically adjusts output to maintain a consistent temperature. This feature minimizes the risk of overheating, ensures energy efficiency, and extends operational lifespan. The film emits far infrared (FIR) rays for comfortable and even heating.

Robust and Safe Design

Manufactured using flame-retardant, eco-friendly polyimide and high purity carbon paste, the XICA PTC Heating Film meets stringent international safety standards, including UL94 V-0 and EN60335-2-96. Its double-layer printing enhances durability, while insulation resistance is rated above 100 M. The film's anti-flammable construction and moisture resistance make it safe for various installations.

Versatile Application and Customization

This flexible film adapts seamlessly to numerous indoor heating needs. Available in customizable sizes up to 1000mm wide and unlimited length, it suits underfloor, wall, or snow melting installations. Compatible with standard voltages (AC 100-240V) and connection types, it integrates into new or existing systems for residential, commercial, and industrial projects.

FAQ's of PTC Heating film (heating film xica ptc two layer printing insulator anti-flammable):

Q: How does the PTC heating film self-regulate its temperature?

A: The XICA PTC heating film uses Positive Temperature Coefficient (PTC) technology, which increases its resistance as the temperature rises. This limits current flow and naturally regulates the temperature, preventing overheating and enhancing both safety and energy efficiency.Q: What installation process is recommended for this heating film?

A: Install the film by direct surface mounting or underfloor placement on dry, level surfaces. It connects via copper busbar soldering or clamping. Ensure compliance with all safety and electrical guidelines, and avoid exposure to excessive moisture during installation for optimal performance.Q: Where can the PTC heating film be used effectively?

A: This heating film is suitable for indoor environments such as homes, offices, walls, underfloor heating, and snow melting systems. Its moisture-resistant, flame-retardant, and thin design makes it ideal for both new construction and retrofitting projects.Q: What are the main benefits of using this PTC heating film?

A: Key advantages include energy-efficient, uniform heating via far infrared emission, self-limiting and safe operation, robust flame resistance, long service life (>30,000 hours), and customization for various sizes and applications. The eco-friendly, non-toxic materials further ensure safe indoor use.Q: Can the power density and size of the heating film be customized for specific projects?

A: Yes, both power density (starting at 110W/m2) and dimensions (up to 1000mm wide, any length) are customizable. This flexibility allows adaptation to diverse heating requirements, from small rooms to large commercial spaces.Q: Is the PTC heating film compliant with international safety standards?

A: Absolutely. The film meets UL94 V-0 fire resistance, EN60335-2-96 electrical safety, and features high insulation resistance (>100 M) plus overheat and short-circuit protection, ensuring reliability across various installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese