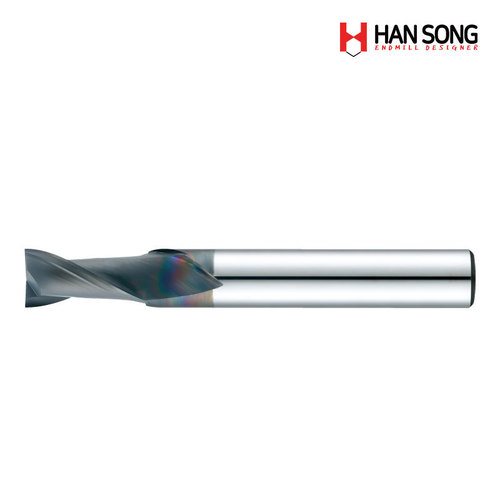

2 Flutes Diamond Coated Rib Ball End Mills (D-pro)

Product Details:

- Surface Finish Ultra-Fine Surface; Mirror Finish

- Diameter 0.2 mm to 6 mm (varies by model)

- Noise Level Low

- Drive Type End Mill Holder

- Lubricating System Dry Machining Recommended

- Shape Ball End

- Features Diamond Coating for Extended Tool Life; High Precision; Excellent Wear Resistance; Suitable for Hard and Brittle Materials

- Click to View more

X

2 Flutes Diamond Coated Rib Ball End Mills (D-pro) Product Specifications

- Ball End

- Diamond Coated

- Diamond Coating

- Diamond Coating for Extended Tool Life; High Precision; Excellent Wear Resistance; Suitable for Hard and Brittle Materials

- Varies by size

- Manual

- Dry Machining Recommended

- Silver with Diamond Coated Finish

- Graphite Machining, High Precision Molding, Rib Machining, Die & Mold Industry

- Standard and Customized Sizes Available

- 2 Flutes Diamond Coated Rib Ball End Mill (D-pro)

- Low

- End Mill Holder

- Ultra-Fine Surface; Mirror Finish

- 0.2 mm to 6 mm (varies by model)

- Solid Carbide

- Varies by model

Product Description

Feature

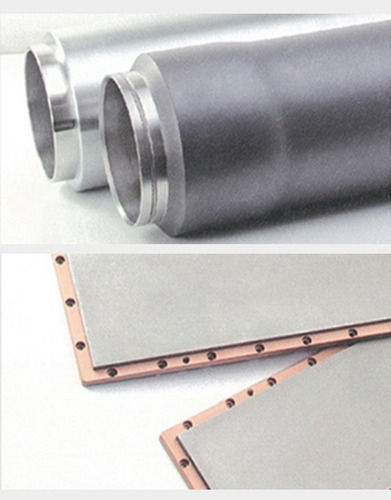

- Designed for cutting Graphite, Copper, Reinforced Plastic, Carbon Fiber and Non-Ferrous Metal.

- The wide range of Effective Length and Overall Length for various work shape.

- MG DIA Improve the performance for the best pure diamond coating.

Company Information

We have been striving for professional manufacturer of MILLING BUR which keeps the same quality from a batch to another batches. Lean process makes it possible to be a competitive in cost and lead time. Intensive development was resulted in broad range tools to fit in many different machine types. We believe that these achievements contribute customers to reach their objective.

The competence of HANSONG M&T is developing and manufacturing END MILL and MILLING BUR. The company will continue the focus on these core technologies to keep the position of professional manufacturer.

Diamond Coating for Advanced Performance

Each D-pro end mill features a diamond coating that provides exceptional wear resistance, allowing for notably longer tool life compared to conventional options. This enables efficient machining of hard and brittle materials, such as ceramics and composites, minimizing downtime and replacement costs within high demand applications.

Engineered for Precision Rib Machining

The cutting edge and helix angle are optimized specifically for rib machining tasks and graphite cutting. This guarantees precise, smooth results with minimal waste, while the unique rib ball end design enhances chip evacuation and maintains surface integrity.

Versatile Application and Low Maintenance

Designed for manual operation, these ball end mills fit standard end mill holders and perform efficiently in dry machining environments. Their ultra-fine, mirror-like surface finish is suitable for high-precision tasks, making them an asset for mold fabrication and complex composite work.

FAQ's of 2 Flutes Diamond Coated Rib Ball End Mills (D-pro):

Q: How does the diamond coating enhance the performance of these 2 flutes rib ball end mills?

A: The diamond coating, with hardness up to 8000 HV, significantly boosts wear resistance and cutting speed, allowing for prolonged tool life and consistent, high-quality surface finishes, especially when machining hard materials like graphite, ceramics, and composites.Q: What specific materials can these end mills be used on?

A: These rib ball end mills are designed for efficient machining of graphite, CFRP (carbon fiber reinforced polymers), ceramics, and various composite materials, making them highly suitable for advanced manufacturing applications.Q: When should I opt for the D-pro over conventional end mills?

A: Choose the D-pro end mills for high precision requirements, especially in rib machining and die & mold industries, where extended tool life, ultra precision tolerance, and superior surface finishes are essential for performance and cost efficiency.Q: Where can these ball end mills be applied in manufacturing processes?

A: The D-pro end mills excel in tasks involving graphite machining, rib creation in molds, high precision molding, and fabrication using composite or ceramic materials. Their versatility makes them ideal for use in tool rooms, die-making, and advanced industrial manufacturing.Q: What is the process for installing and using these end mills?

A: Installation is straightforward, as the end mills are compatible with standard end mill holders. Manual operation is recommended, and for optimal results, dry machining should be employed to prevent material contamination and achieve ultra-fine surface finishes.Q: How does the rib design affect chip evacuation during machining?

A: The rib design improves chip evacuation by efficiently channeling debris away from the cutting zone. This minimizes clogging and helps maintain cutting performance, especially important during intricate rib machining and graphite cutting.Q: What are the main benefits of using these diamond coated ball end mills in my operation?

A: Key benefits include prolonged tool life, exceptional wear resistance, low noise operation, precise surface finishes, and superior results when working with tough or brittle materials. These advantages collectively contribute to improved productivity and reduced operational costs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese