Threaded Coupler

Product Details:

- Installation Type Threaded

- Diameter M12 to M32 (varies as per requirement)

- Features Easy to Install, Reliable Connection

- Machines Type Rebar Threading Machine Compatible

- Form Solid

- Color Silver / Grey

- Application Construction, Civil Engineering, Structural Columns & Beams

- Click to View more

X

Threaded Coupler Price And Quantity

- 1000 Unit

Threaded Coupler Product Specifications

- Standard as per design (varies with size)

- 12mm, 16mm, 20mm, 25mm (customized available)

- 98% minimum (based on steel composition)

- Cylinder / Round

- High Strength, Corrosion Resistant, Durable

- EN8 / EN18 / Customized Grades

- Construction, Civil Engineering, Structural Columns & Beams

- Joining Steel Bars in RCC Structures

- Upto 600 MPa Tensile Strength

- Silver / Grey

- Rebar Threading Machine Compatible

- Solid

- Galvanized / Zinc Plated

- Threaded

- 100g to 800g (depending on size)

- Threaded Coupler

- Easy to Install, Reliable Connection

- M12 to M32 (varies as per requirement)

- Carbon Steel

Threaded Coupler Trade Information

- Telegraphic Transfer (T/T)

- Yes

- Woven bag + pallet

- ISO9001, ISO14001, Patent

Product Description

Product DescriptionIt is a mechanical joint system that connects rebars to rebars in general construction works and civil engineering works.

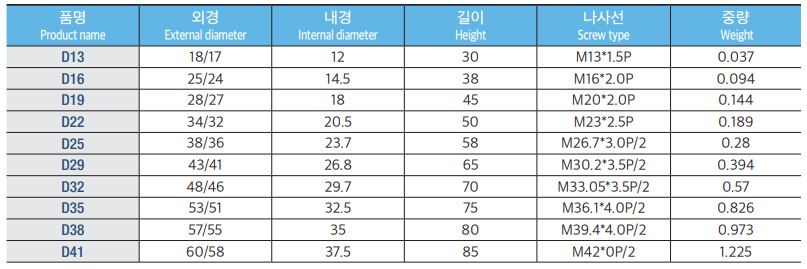

Product Specification

D13 - D32

Product Feature

The existing method could only be connected by threading the rebar, but it is a device that can be connected smartly without the need for machining the rebar of our company.

Construction site, civil engineering site, basic construction site, bridge construction site, etc.;

Exceptional Strength and Compatibility

Our threaded coupler delivers tensile strengths up to 700 MPa and is engineered for compatibility with ISO Metric threads and standard rebar threading machines. Precision-threaded female connections on both ends provide secure joins for structural stability, ensuring reliability in demanding construction environments.

Corrosion Resistance and Durability

Each coupler is galvanized or zinc-plated, granting outstanding corrosion resistance for long-lasting use in varied conditions. The solid, carbon steel construction (EN8/EN18) further guarantees performance across temperature ranges from -20C to 80C, making this coupler suitable for projects in harsh or fluctuating climates.

Customizable for Project Needs

Available in standard sizes from 12mm to 25mm with customization possible, our couplers support diverse structural requirements. Purity levels above 98% ensure robust compositions, while flexible packaging (box or bag) and size options support tailored logistics for distributors, exporters, and contractors.

FAQs of Threaded Coupler:

Q: How is the threaded coupler installed in RCC structures?

A: Installation is straightforward: the couplers female ends are threaded onto prepared steel bars using a rebar threading machine. The bars are inserted until securely connected, ensuring reliable transfer of strength across the joint.Q: What standards and quality codes does the threaded coupler comply with?

A: This coupler conforms to IS, ACI, or BS codes as specified for individual projects, ensuring suitability for international and regional construction standards.Q: When should I choose a galvanized coupler over a zinc-plated one?

A: Galvanized and zinc-plated couplers both offer strong corrosion resistance. Choose galvanized couplers for environments with prolonged exposure to moisture or aggressive agents, and zinc-plated ones for general construction where moderate resistance is sufficient.Q: Where are threaded couplers commonly used in construction?

A: Threaded couplers are widely used in connecting steel reinforcement bars in columns, beams, and other load-bearing RCC structures, particularly in civil engineering and infrastructure projects.Q: What are the main benefits of using this threaded coupler?

A: Benefits include high tensile strength (up to 700 MPa), excellent corrosion resistance, durability, ease of installation, and a reliable mechanical connection, all of which enhance structural integrity and project efficiency.Q: How does the manufacturing process ensure product quality and precision?

A: Each coupler is machined and precision-threaded, followed by rigorous quality checks to ensure accurate dimensions, reliable fitment, and adherence to required strength and surface standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese